Development of Technology for Processing pf Fine-Grained Fraction of Chiatura Manganese Ore

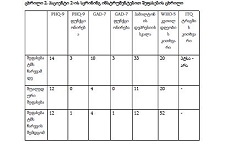

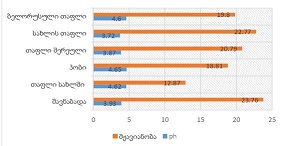

Downloads

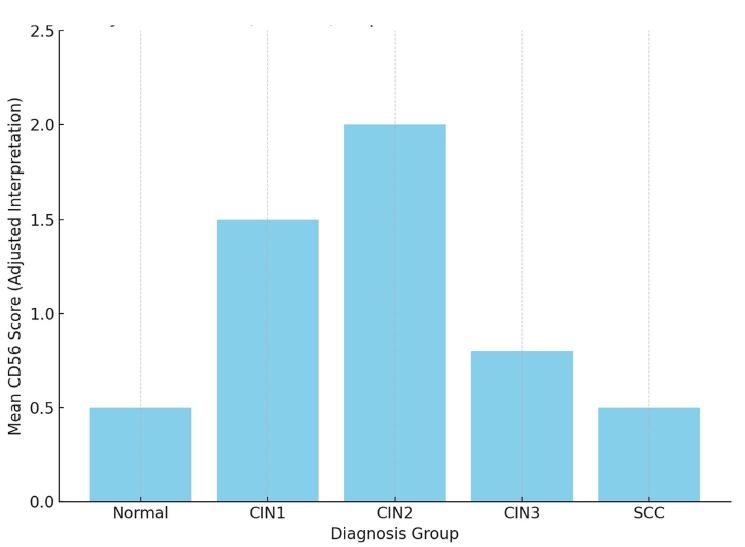

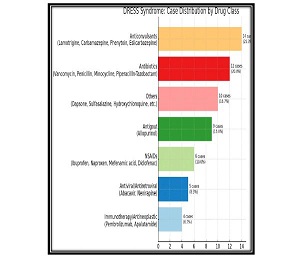

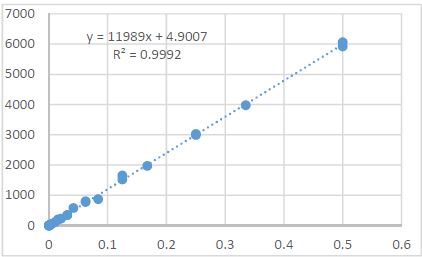

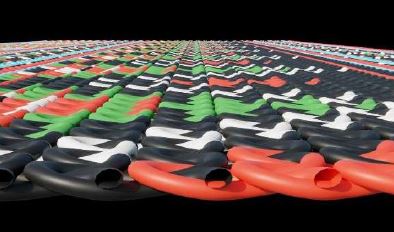

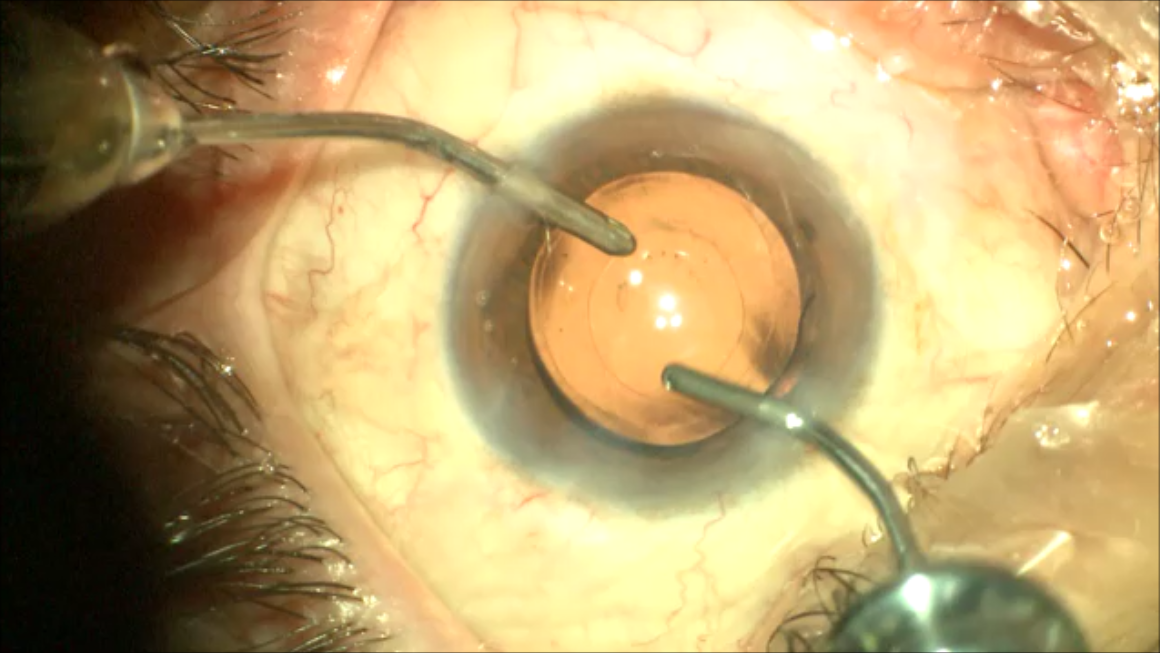

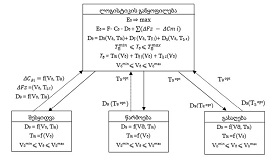

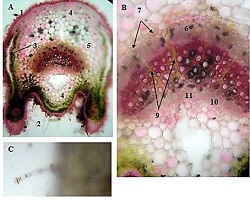

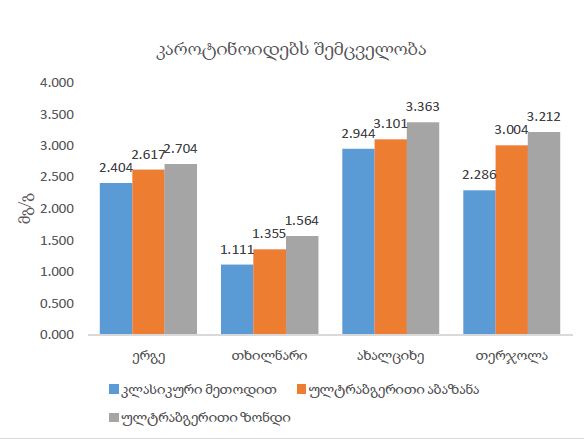

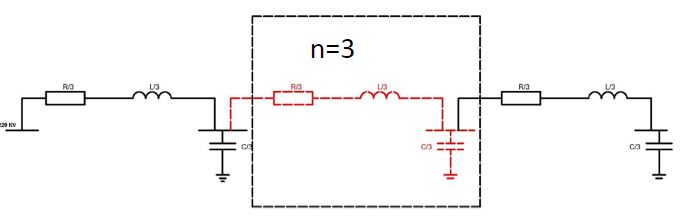

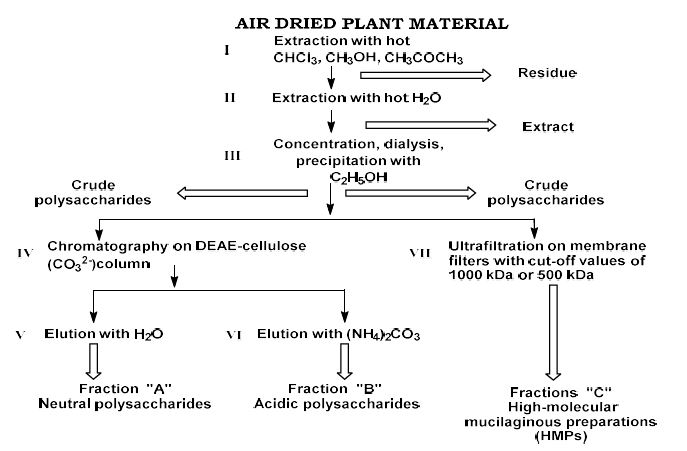

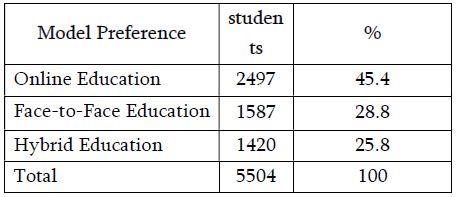

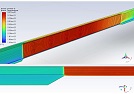

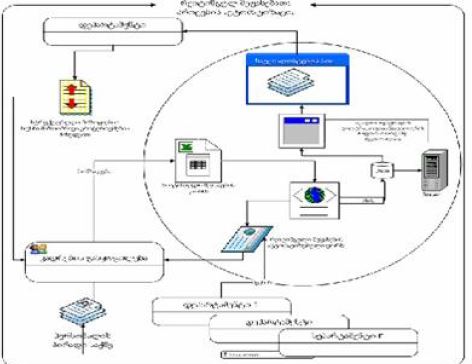

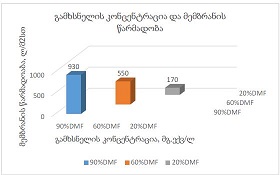

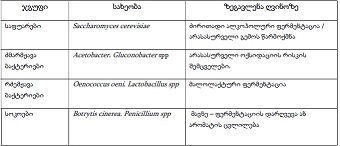

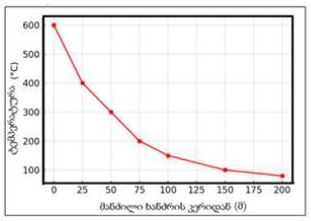

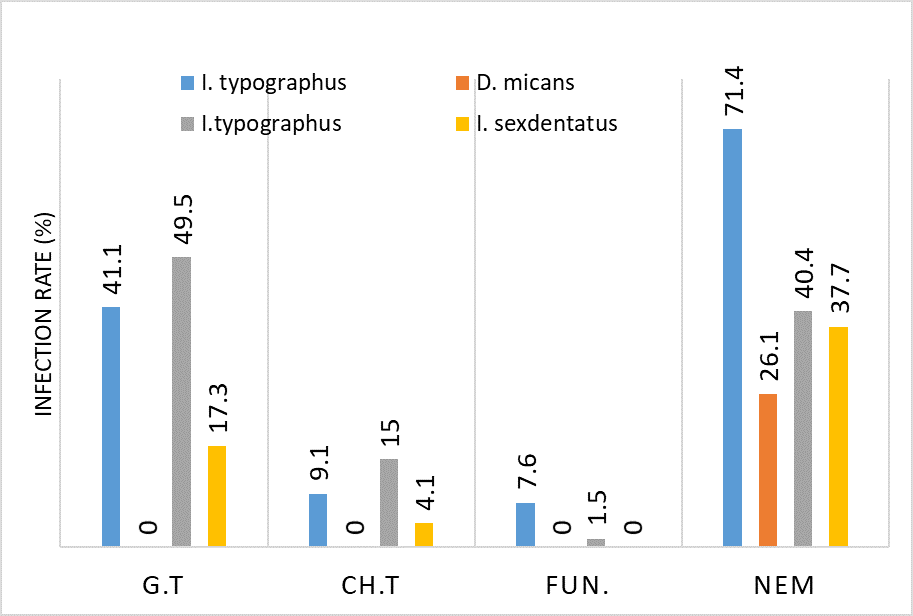

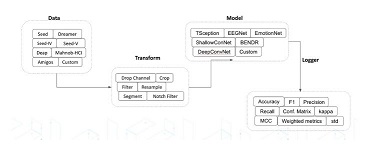

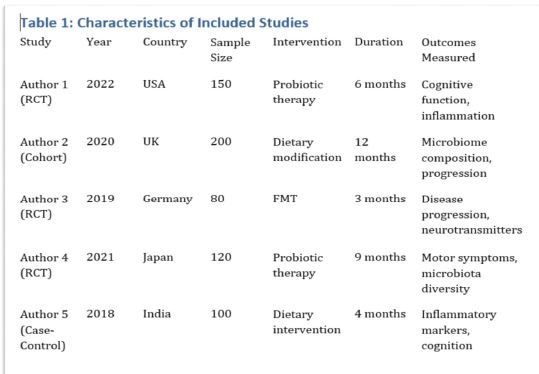

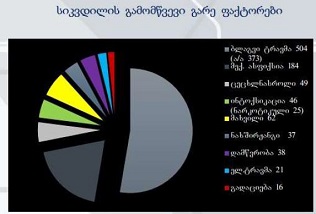

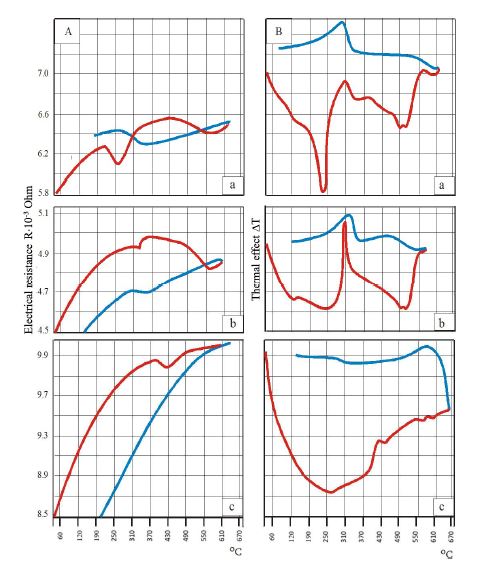

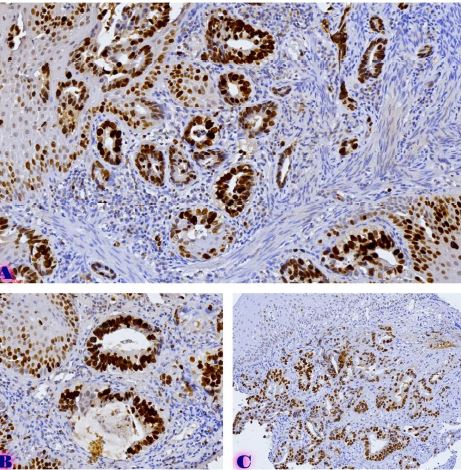

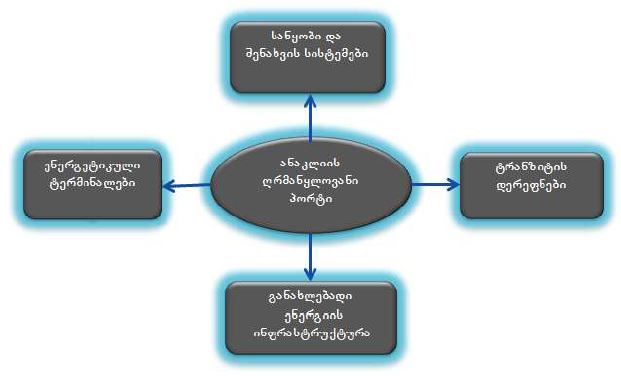

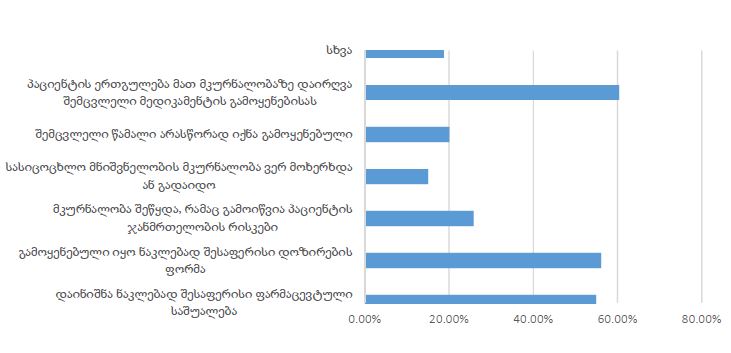

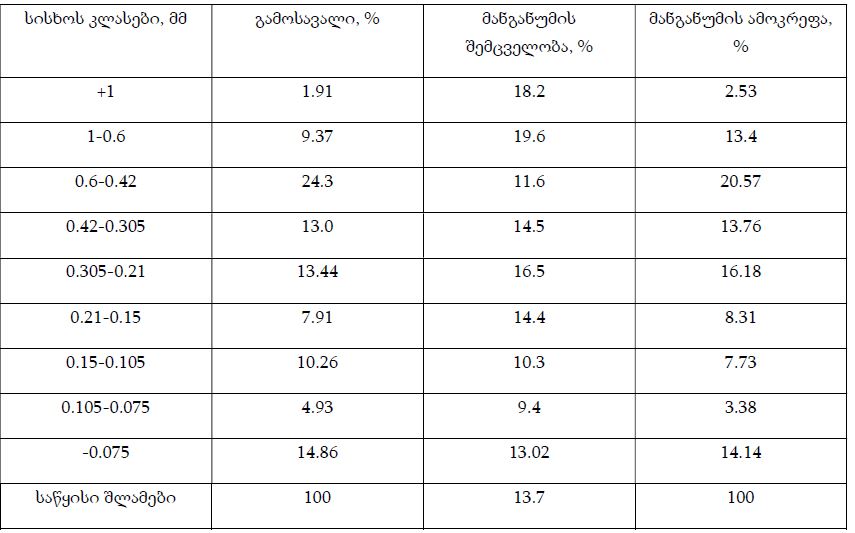

Chiatura manganese ores are categorized as sedimentary rocks with a high clay content. For the comprehensive processing technology, it is necessary to remove the clay fraction from the ores what is done by washing. Washing produces washed material and sludges. The washed material, following the preliminary classification, undergoes gravity treatment (sedimentation) to produce a marketable product. The sludges, which, in addition to clay-containing minerals, retain large amount of fine-grained (-1 mm) manganese fractions, are not processed and are discharged into the freshwater water basins. The manganese content in the sludge varies within 12-16%. Studies conducted on the extraction of manganese fraction from the sludge do not currently allow full recovery of marketable products. The paper discusses the results of the research conducted to develop a comprehensive technology of manganese sludge beneficiation. According to the technology developed as a result of the research, manganese concentrate of the 3rd grade, recovery of 25.22%, manganese content of 37.8% and recovery of 69.6% was obtained from the sludge with manganese content of 13.7%. Thus, the developed technology makes it possible to obtain additional marketable products from sludge and, accordingly, significantly to improve the natural environment of the Kvirila and Rioni river basins [1-4].

Downloads

Богданович А.В. Исследование работы гравитационных сепараторов для обогащения тонкозернистых материалов. ж. Обогащение руд. 2019. №1. изд-во „Руда и Металлы“;

Федотов К.В. Тютюнин В.В. Обогащение центробежных концентраторах. монография - Иркутск. изд-во ИрГГУ-2019;

J.SHUBITIDZE, A.(SANDRO) KHIZANISHVILI, K. KEKELIDZE, A.ABSHILAVA, D. TALAKHADZE, Z. ARABIDZE. INVESTIGATION OF POSSIBILITY OF ADDITIONAL BENEFICIATION OF FLOTATION TAILINGS AT RMG COPPER PROGESSING PLANT; THE DEVELOPMENT OF MINING AND GEOLOGY IS THE PRECONDITION FOR THE REVIVAL OF ECONOMY; 9th International Scientific-Practical Conference on Up-to-date Problems of Mining and Geology; 28-29 September, 2023, Tbilisi; Technical University; pp. 155-6158;

Zhu X., Tao Y., Zhang L. Numerical simulation of flow field in enhanced gravity concentrator. Physicochemical Problems of Mineral Processing. 2018. Vol. 54. No 3. Pp. 975—980. 12.

Copyright (c) 2025 Georgian Scientists

This work is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License.