Indentation induced structural changes in boron-doped silicon irradiated with electrons

Downloads

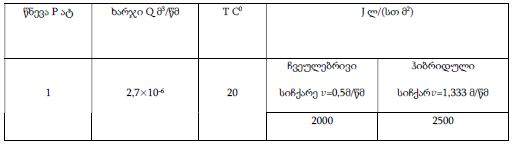

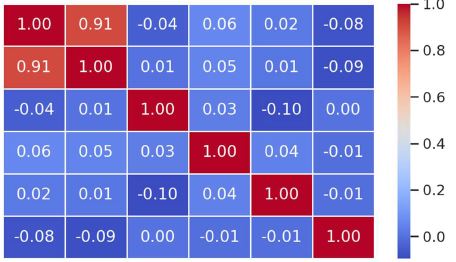

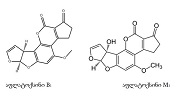

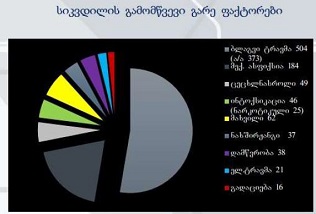

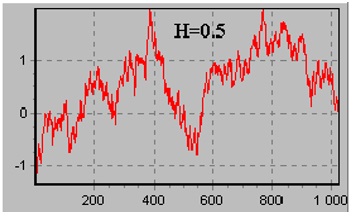

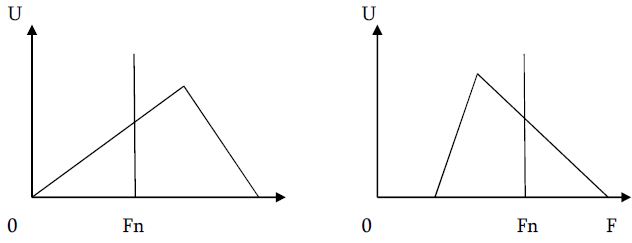

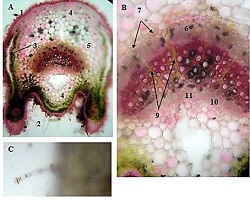

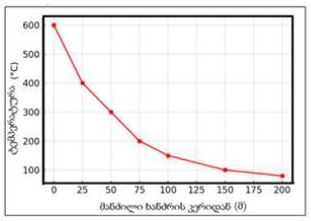

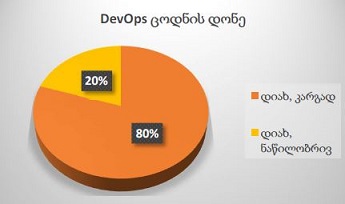

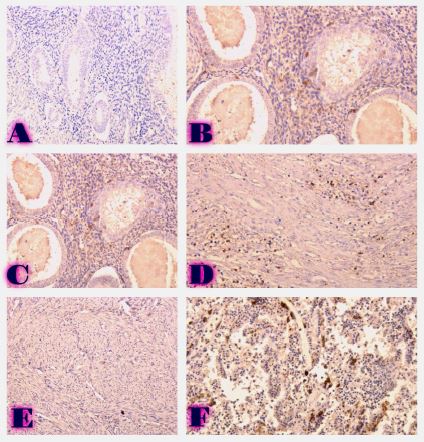

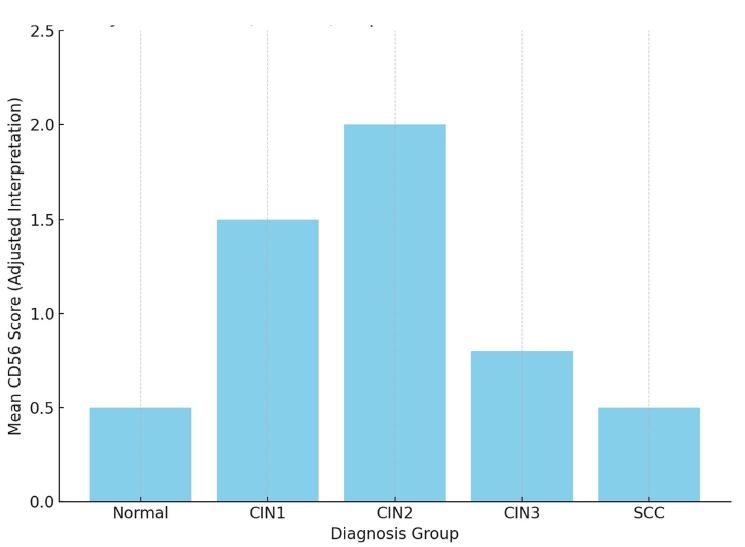

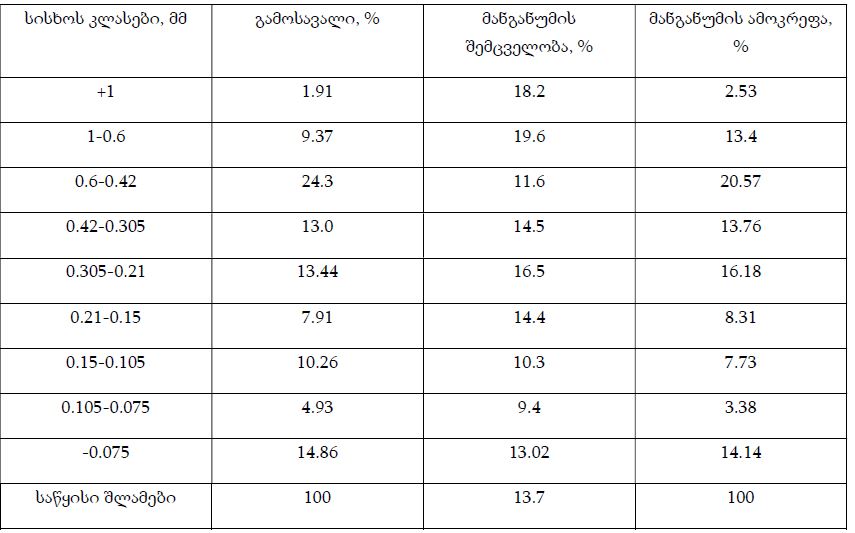

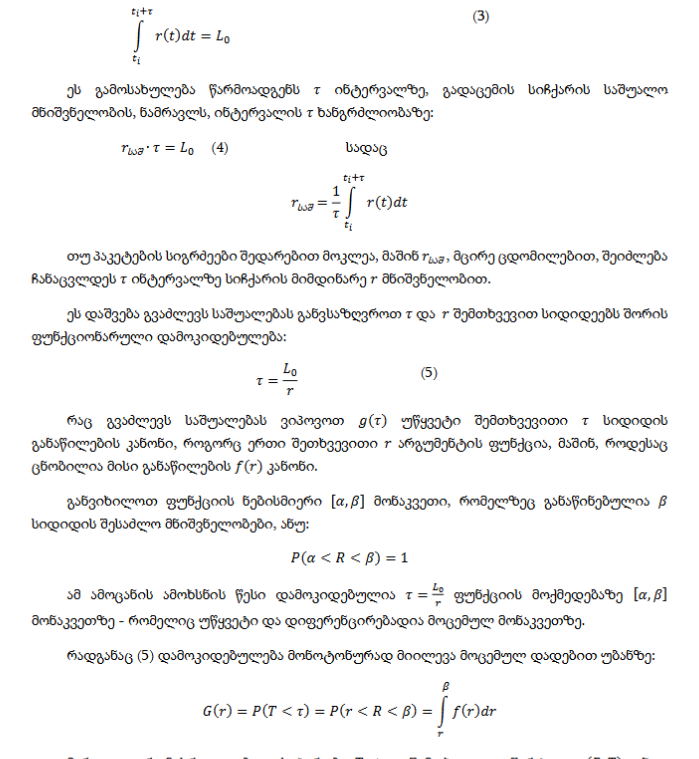

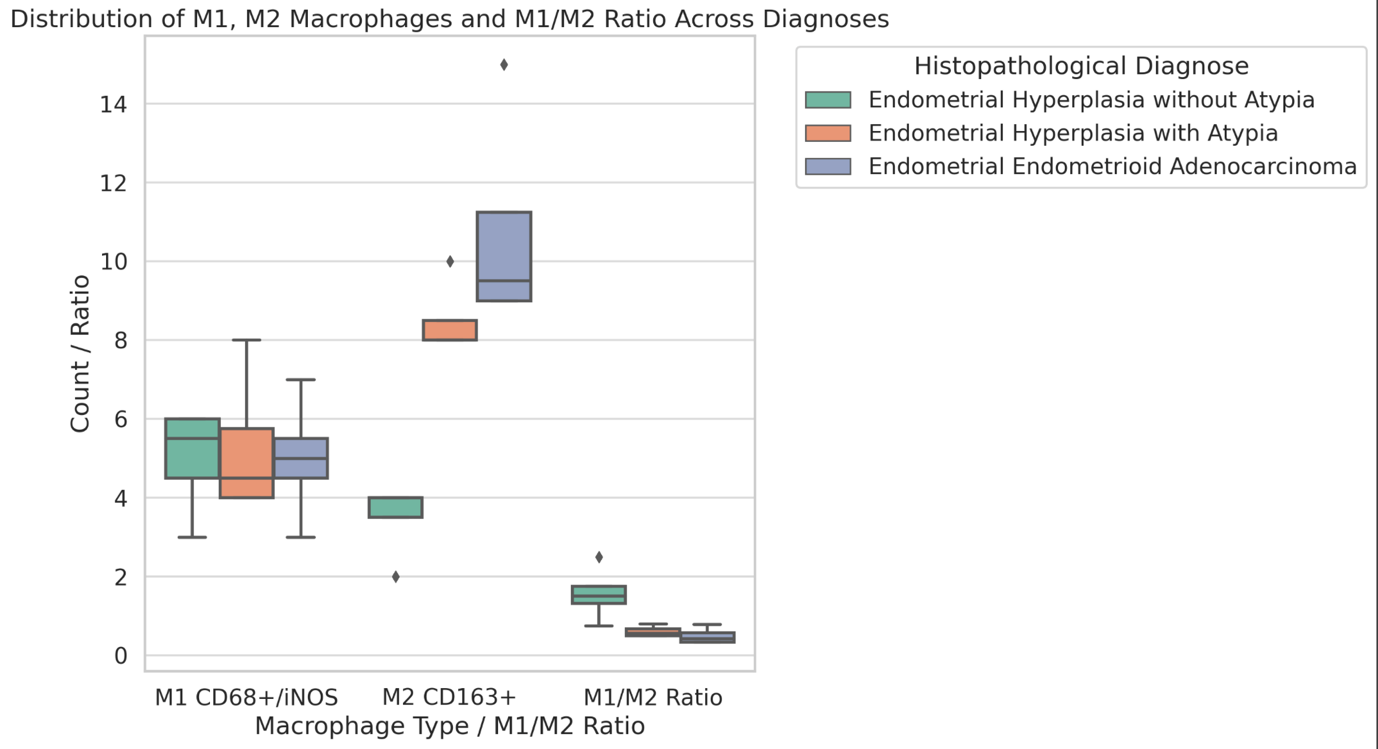

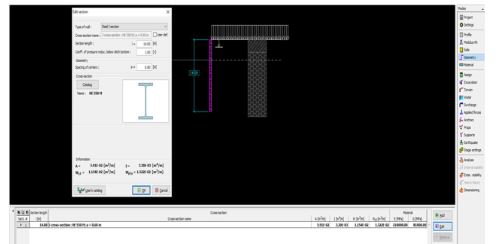

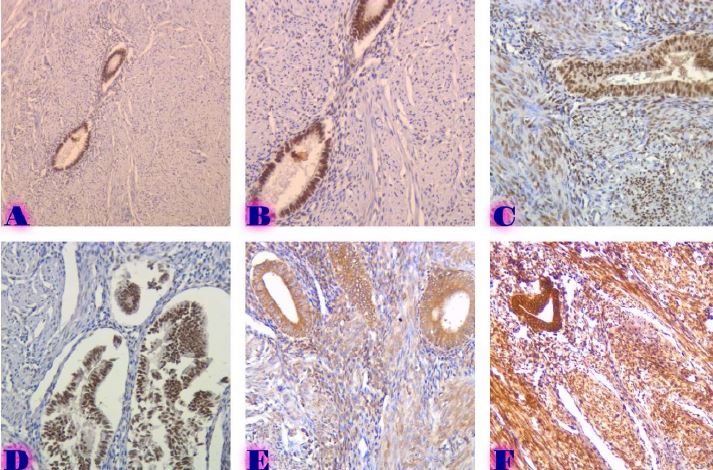

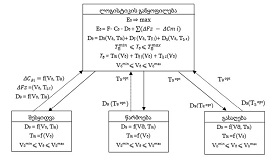

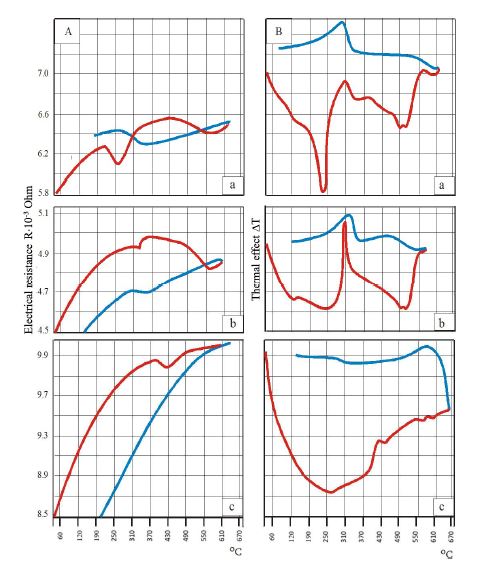

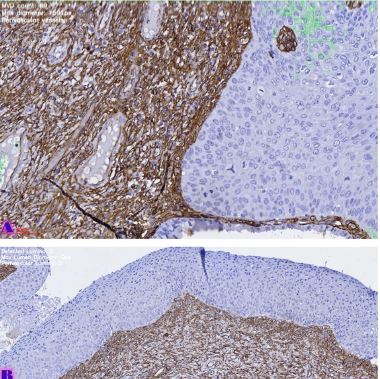

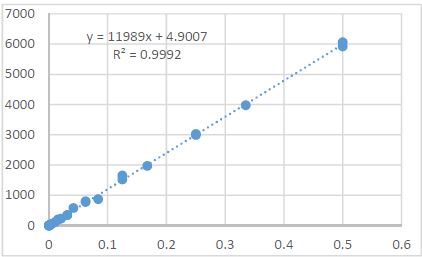

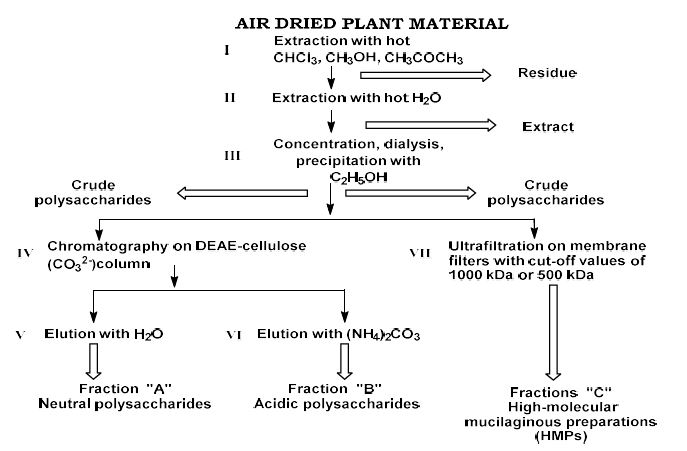

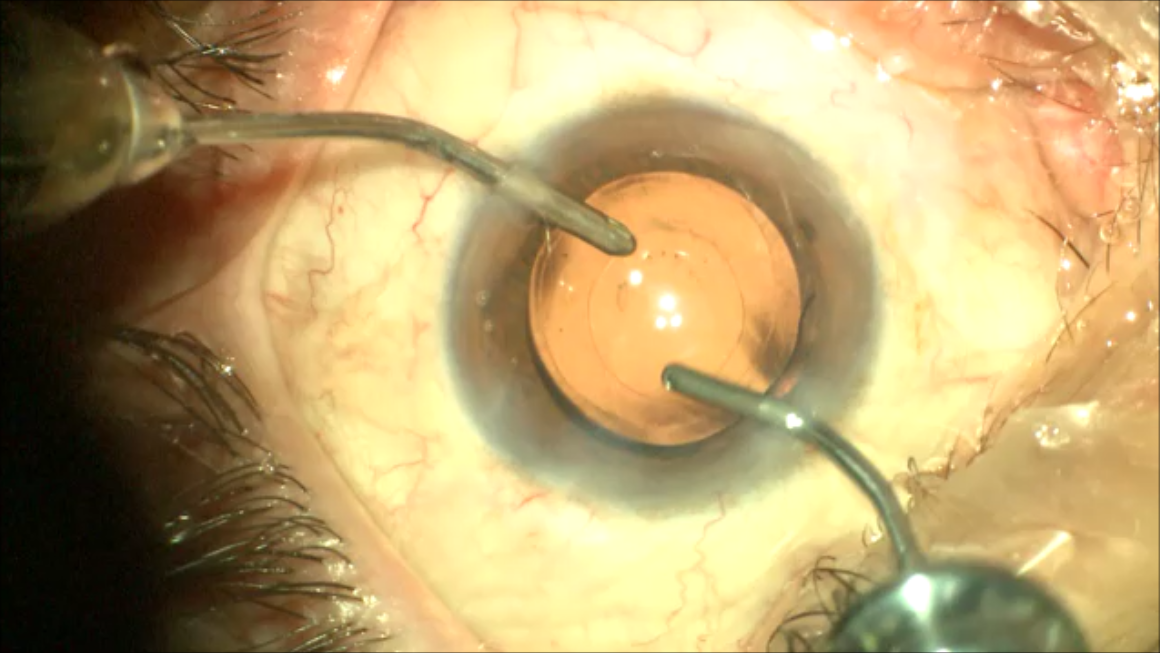

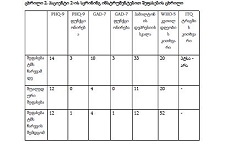

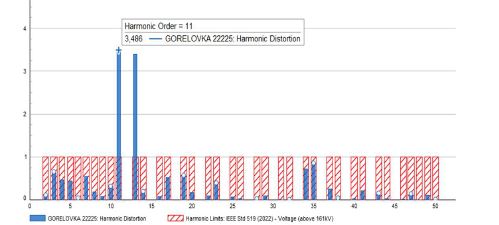

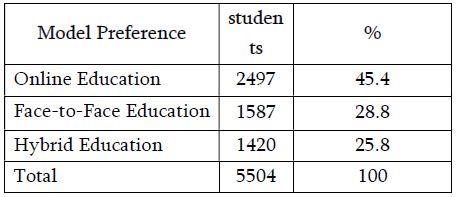

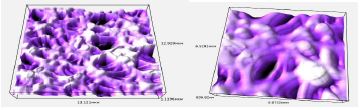

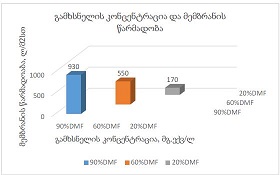

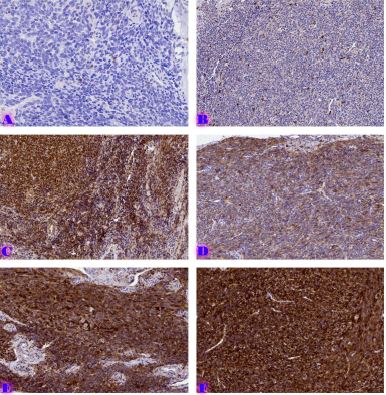

A complex study of the microstructure, electrophysical properties, and structural phase transformations in the processes of ultramicroindentation of boron-doped monocrystalline silicon substrates with (111) crystallographic orientation in the initial and irradiated state was carried out. It is shown, that irradiation of p-Si samples by 12 meV energy electrons with fluences 1013 cm-2 stipulates decrease of the specific electrical resistivity by 3 times and holes mobility by 20% . In infrared absorption spectra of the electron irradiated samples, decrease of the oxygen and carbon atoms concentration by 2,5 -3 times is detected. By Load-displacement measurements during the indentation processes with a Vickers indenter on the (111) planes of the research sample irradiated with electrons a weak increase of the elastic modulus and the average contact pressure corresponding to the transformations of the unstable phases of silicon is revealed. The contribution of electron irradiation modified dislocation atmospheres in the characteristics of electrophysical properties and structural phase changes carried out in the indentation processes in boron-doped silicon is discussed. The reasons for the variation of the dynamic mechanical and electrophysical properties related to the modification of dislocation structure atmospheres induced by electron irradiation in monocrystalline p-Si : B samples are analyzed.

Downloads

G.Ge., V.Domnich., Y. Gogotsi J.Appl Phys., 93, [2003], 2418-2423

Li Chang, Liangchi Zhang. J. Mater Sci. and Engineering, A506 (2009), 125-129.

C.R.Das, S.Dhara, Yeau-Ren Yeng, J.Appl. Phys. Letters, 96. (2010), 253113-1-25313-

A.Kailer, Y.G.Gogotsi, and K.G.Nickel. J.Appl. Phys. 81,7, (1997), 3057-3063.

T.Juliano, V.Domnich, and Y.Gogotsi, J.Mater Res., vol. 19, No 10 (2004), 3099-3108.

L.Chang, L.C.Zhang. J.Acta Materialia, 57 (2009), 2148-2153.

T.Juliano, Y.Gogotsi, and V.Domnich. J.Mater Res., Vol.18, No5 (2003), 1192-1201.

W.C.Oliver and G.M.Pharr. J.Mater. Res., 7. (1992), 1564-1583.

N.V.Novikov, S.N.Dub, Y.V.Milman, Y.V.Gridneva, and S,Y.Chugunova. J.Superhard.

Mater, Vol.18, No 32 (19960, 1009-1017.

R.F.Cook. J.Mater.Sci. 41 (2006), 841-872.

S.Wang, B.Haberl, Y.S.Williams, and I.E.Bradby.J.Appl.Phys.Letters, 106, 252.103 (2015)

V.Domnich and Y.Gogotsi. J App. Phys.Letters, V.76, N16 (2000), 2214-2218

Copyright (c) 2023 GEORGIAN SCIENTISTS

This work is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License.