Design and Evaluation of an Energy-Efficient Automated Greenhouse Management System for Optimized Microclimate Control

Downloads

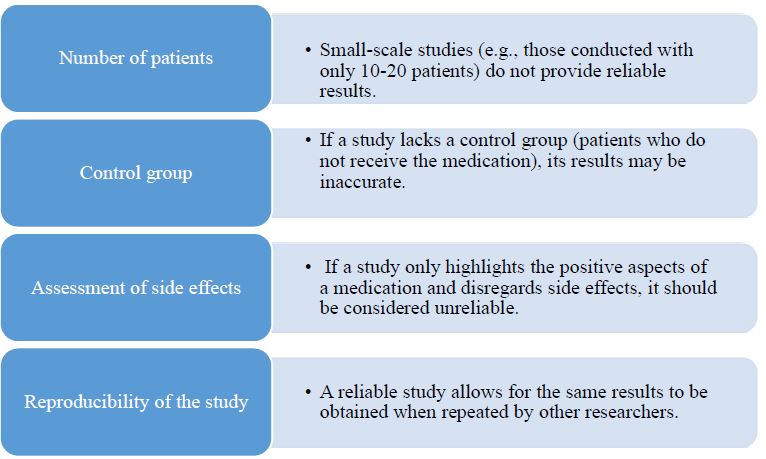

Energy consumption and microclimate instability remain critical challenges in modern greenhouse agriculture, particularly under conditions of rising energy costs and increasing climate variability. Efficient regulation of temperature, humidity, lighting, and irrigation is essential for maintaining high crop productivity while minimizing resource losses. This study proposes an automated, energy-efficient greenhouse management system designed to optimize environmental control processes through continuous monitoring and intelligent regulation.

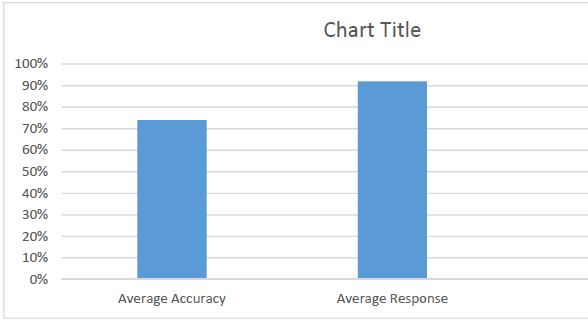

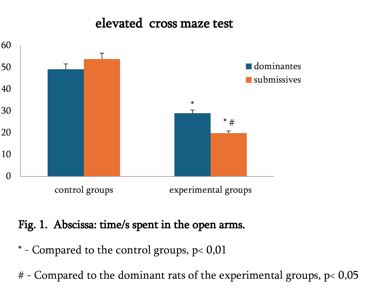

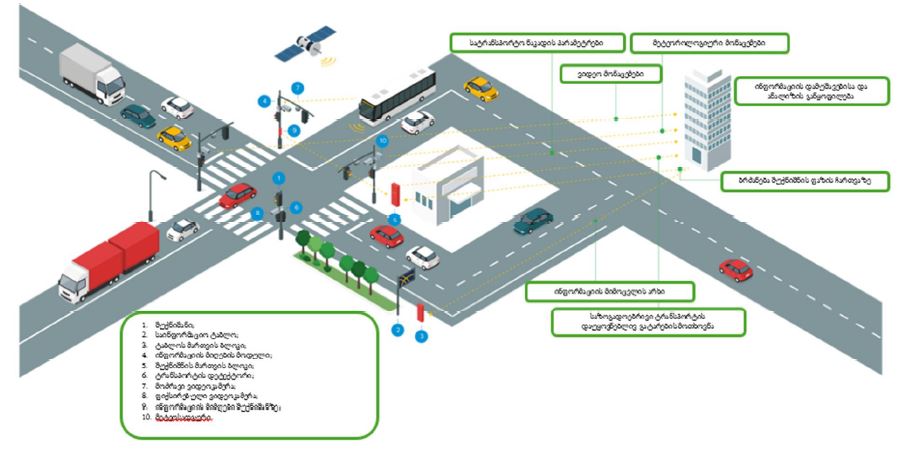

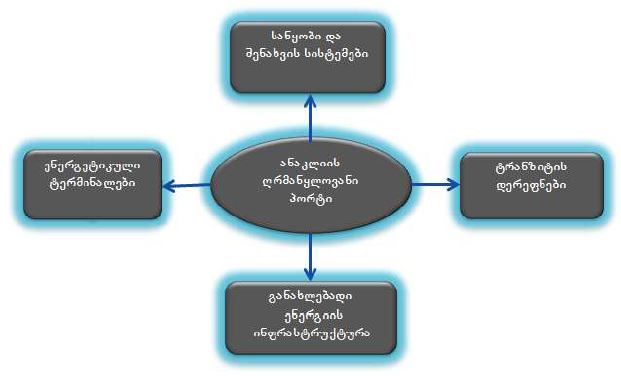

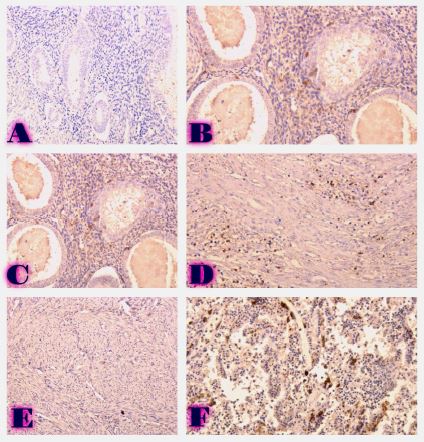

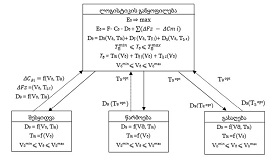

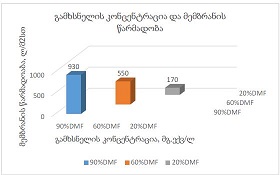

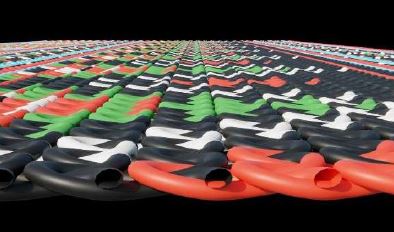

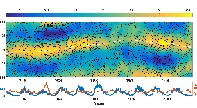

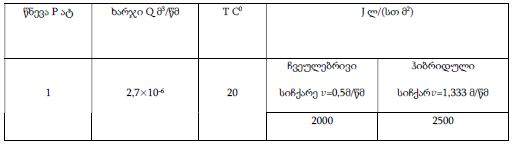

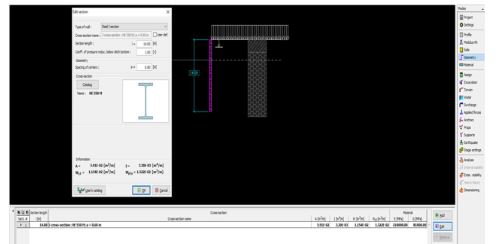

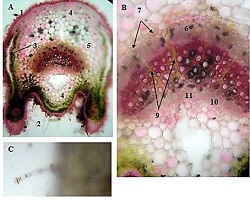

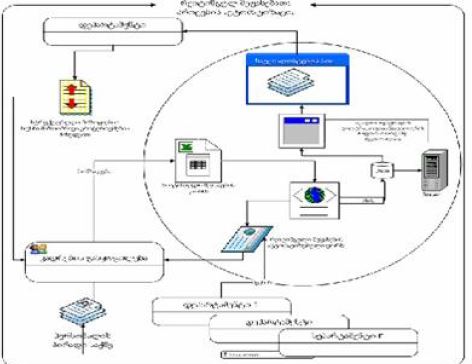

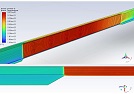

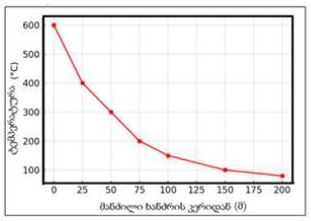

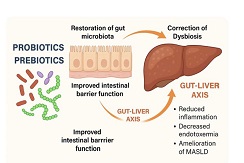

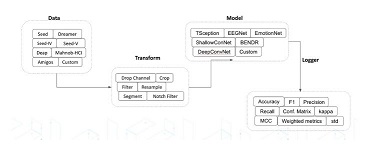

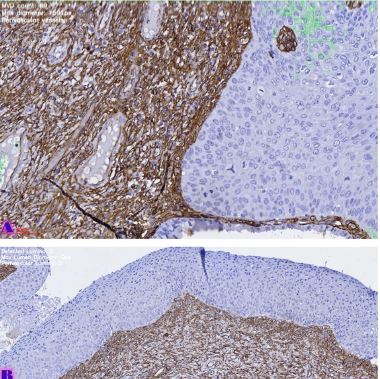

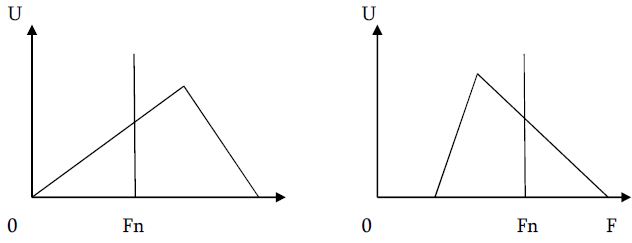

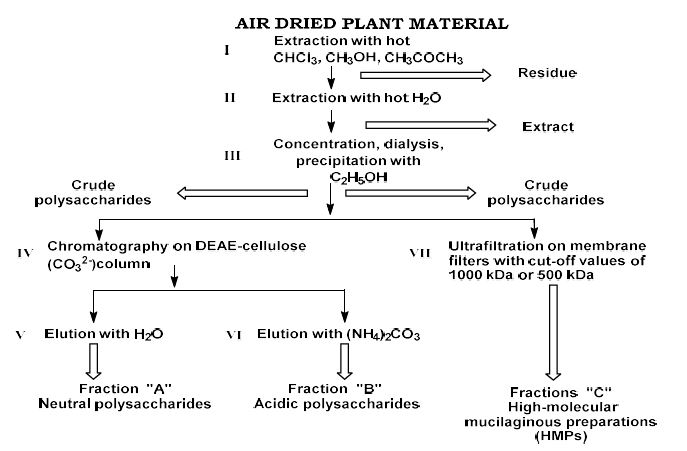

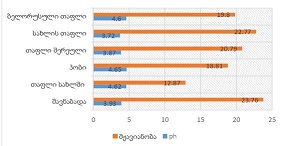

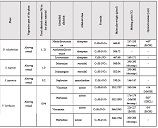

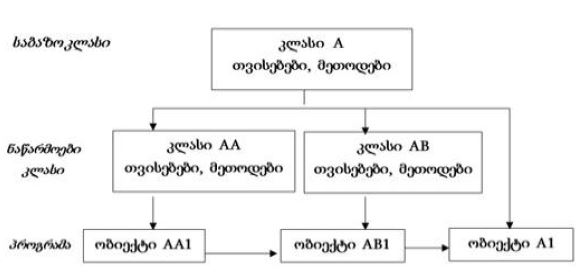

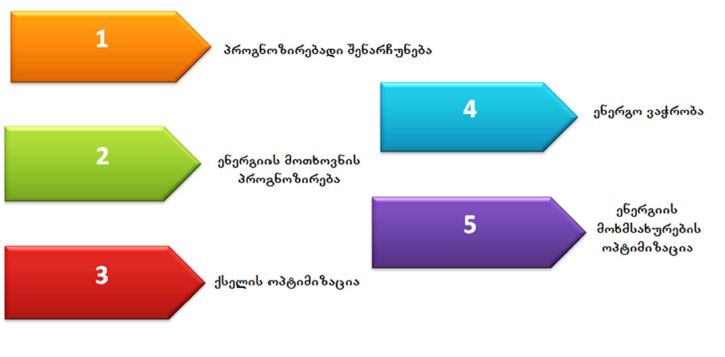

The developed system combines sensor-based data acquisition with centralized control strategies to manage heating, ventilation, lighting, and irrigation in an integrated manner. A key innovation of the research is the application of a soil-assisted air circulation approach for humidity control, which enables moisture removal through condensation while simultaneously contributing to soil water balance. Experimental validation confirms that this approach enhances humidity stabilization and reduces the overall energy demand of greenhouse operation.

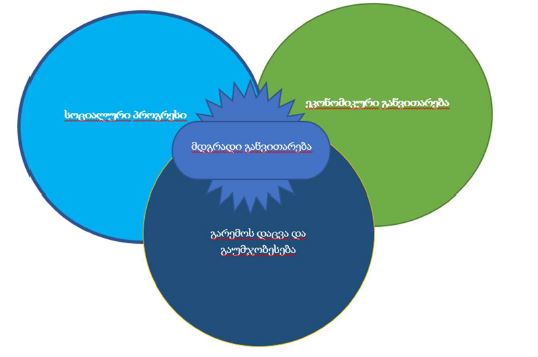

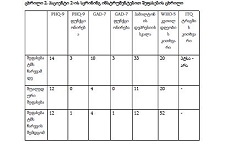

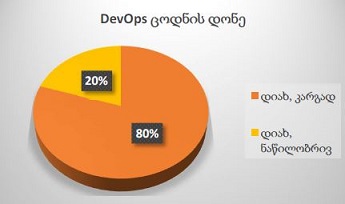

The research methodology involves system design, algorithm development for automated control, and experimental testing under real greenhouse conditions. Performance evaluation focuses on energy efficiency, environmental stability, and the operational reliability of the proposed solution. The results demonstrate that intelligent automation significantly improves microclimate regulation and resource utilization compared to conventional greenhouse management practices.

This study contributes to the advancement of sustainable greenhouse technologies by presenting a practical and scalable management framework that supports energy-efficient agricultural production. The proposed system has strong potential for application in modern greenhouse enterprises, educational initiatives, and national strategies aimed at improving resource efficiency and agricultural resilience.

Downloads

Boulard, T., & Wang, S. (2002). Greenhouse crop transpiration simulation from external climate conditions. Agricultural and Forest Meteorology, 100(1), 25–34. https://doi.org/10.1016/S0168-1923(99)00089-9

Castellano, S., Scarascia Mugnozza, G., Russo, G., Briassoulis, D., Mistriotis, A., Hemming, S., & Waaijenberg, D. (2008). Plastic nets in agriculture: A general review of types and applications. Applied Engineering in Agriculture, 24(6), 799–808. https://doi.org/10.13031/2013.25320

Körner, O., & Challa, H. (2003). Process-based humidity control regime for greenhouse crops. Computers and Electronics in Agriculture, 39(3), 173–192. https://doi.org/10.1016/S0168-1699(03)00079-1

Li, T., Heuvelink, E., & Marcelis, L. F. M. (2014). Quantifying the source–sink balance and its impacts on plant growth and development. Plant, Cell & Environment, 38(10), 1876–1890. https://doi.org/10.1111/pce.12460

López, A., Valera, D. L., Molina-Aiz, F. D., Peña, A., & Marín, P. (2017). Field analysis of a greenhouse with underground air distribution system. Biosystems Engineering, 155, 33–45. https://doi.org/10.1016/j.biosystemseng.2016.12.003

Montero, J. I., Antón, A., Muñoz, P., & Lorenzo, P. (2011). Transpiration from greenhouse crops. Acta Horticulturae, 893, 345–352. https://doi.org/10.17660/ActaHortic.2011.893.36

Nelson, J. A., Bugbee, B., & Hopper, N. W. (2020). Economic analysis of greenhouse lighting: LED vs. high pressure sodium fixtures. HortScience, 55(3), 361–372. https://doi.org/10.21273/HORTSCI14639-19

Pérez-Parra, J., Baeza, E., Montero, J. I., & Bailey, B. J. (2004). Natural ventilation of greenhouses with continuous roof vents. Biosystems Engineering, 88(2), 227–239. https://doi.org/10.1016/j.biosystemseng.2004.03.007

Shamshiri, R. R., Kalantari, F., Ting, K. C., Thorp, K. R., Hameed, I. A., Weltzien, C., Ahmad, D., & Shad, Z. M. (2018). Advances in greenhouse automation and controlled environment agriculture. Biosystems Engineering, 170, 1–22. https://doi.org/10.1016/j.biosystemseng.2018.02.006

Otkhozoria, N., Otkhozoria, V., Narchemashvili, M. (2021) Fractality Of Measurements Of Quantities And Real Processes. International Trends In Science And Technology, Engineering Sciences June 2021 Doi: https://doi.org/10.31435/rsglobal_conf/30062021/7620

Chkheidze, I., Otkhozoria, N., & Narchemashvili, M. (2021). EVALUATION OF MEASUREMENT QUALITY USING THE MONTE-CARLO METHOD. Universum, 65-70. DOI: 10.32743/UniTech.2021.84.3-4.65-70

Sharashenidze, N., Otkhozoria, N., & Menabde, T. (2024). Ultrasonic distance measurement and system simulation. Georgian Scientists, 6(1), 20–25. https://doi.org/10.52340/gs.2024.06.01.04

Singh, M. C., Singh, J. P., & Singh, K. G. (2016). Energy efficient greenhouse structures and climate control systems. Renewable and Sustainable Energy Reviews, 54, 299–314. https://doi.org/10.1016/j.rser.2015.10.022

Sethi, V. P., & Sharma, S. K. (2007). Survey of cooling technologies for worldwide agricultural greenhouse applications. Solar Energy, 81(12), 1447–1459. https://doi.org/10.1016/j.solener.2007.06.004

van Straten, G., van Willigenburg, L. G., van Henten, E. J., & van Ooteghem, R. J. C. (2010). Optimal Control of Greenhouse Cultivation. CRC Press.

Wang, S., & Boulard, T. (2000). Predicting greenhouse climate by neural networks. Agricultural and Forest Meteorology, 104(1), 49–65. https://doi.org/10.1016/S0168-1923(00)00141-5

Xu, J., Li, Y., Wang, R., & Liu, W. (2021). Energy-saving control strategies for greenhouse environment based on sensor networks. Energy Reports, 7, 383–392. https://doi.org/10.1016/j.egyr.2021.01.012

World Bank. (2020). Energy-efficient technologies for sustainable greenhouse production. Washington, DC: World Bank Group.

Copyright (c) 2026 Georgian Scientists

This work is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License.