Best Practices and Challenges in Diagnostic and Monitoring Methods of Technological Equipment in Manufacturing Processes

Downloads

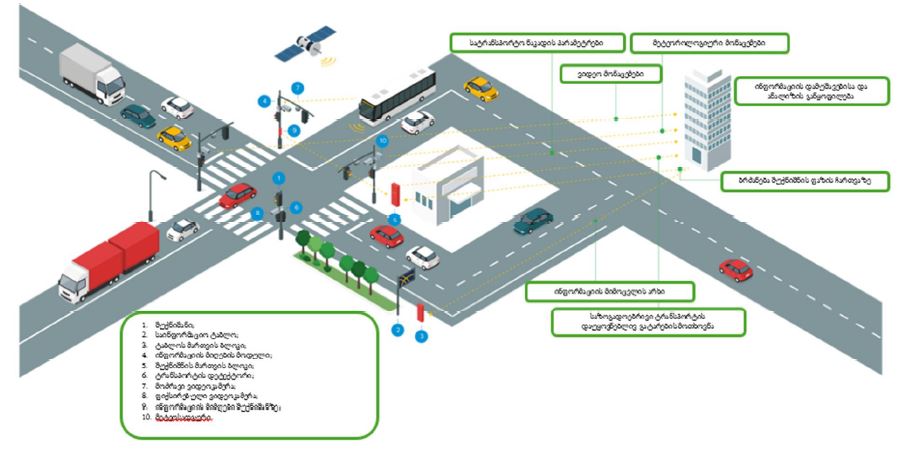

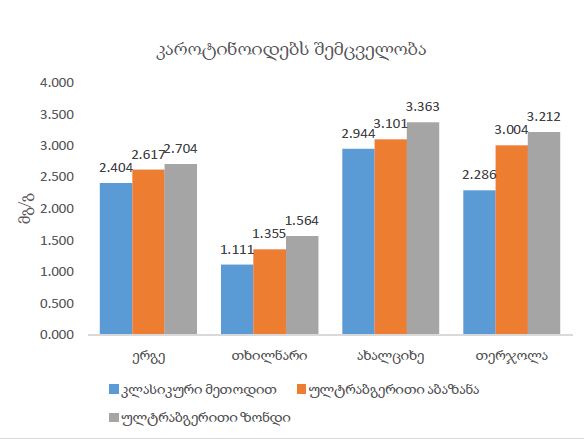

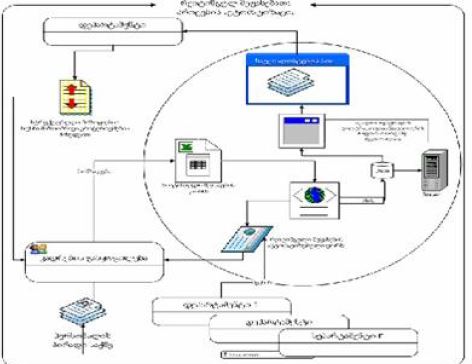

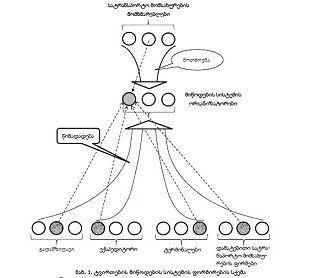

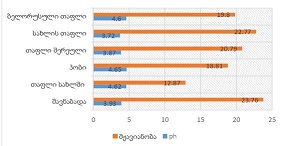

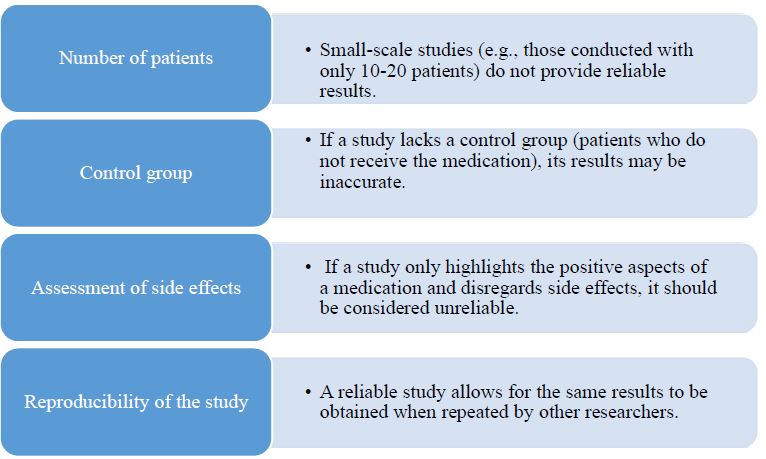

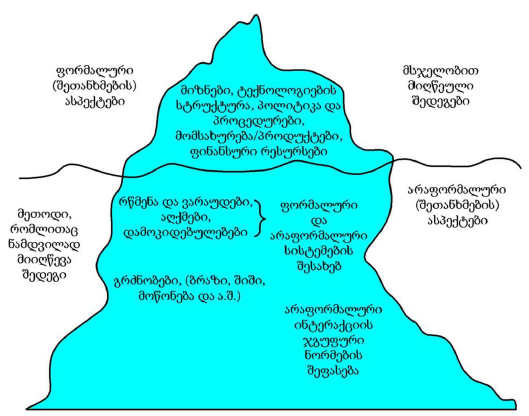

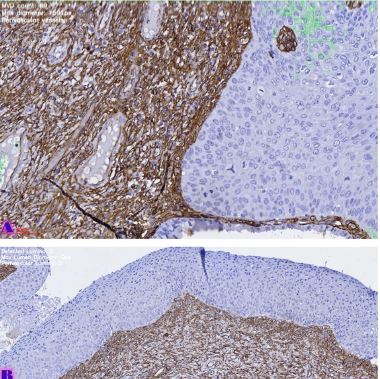

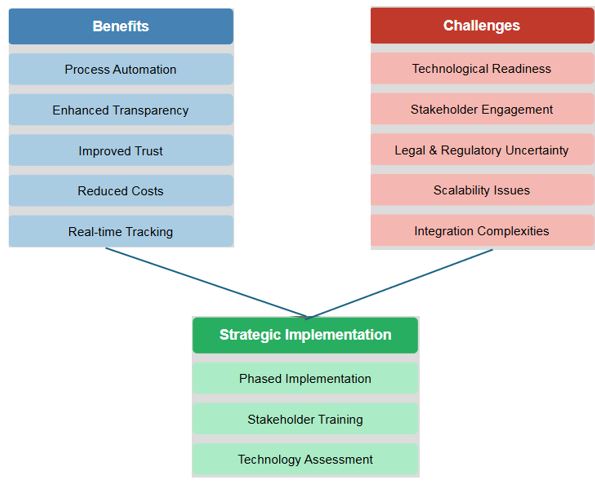

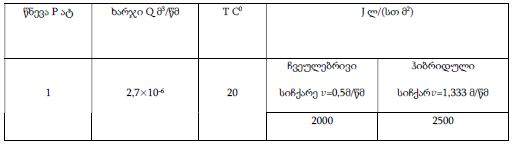

In modern manufacturing, the reliability and efficiency of technological equipment, such as machine tools and industrial robots, are critical for competitiveness. This article explores diagnostic and monitoring methods, focusing on best practices like continuous monitoring, predictive maintenance, and self-control systems, which reduce unplanned downtime and optimize costs. It also addresses challenges, including organizational, economic, and technical difficulties, as well as data reliability issues. Practical solutions, such as personnel training and system integration, are proposed to enhance production reliability. The study aims to promote the adoption of these methods in the Georgian industry.

Downloads

Smith, J. Industrial Equipment Monitoring: Best Practices and Challenges. Journal of Manufacturing Systems. 2023. 45(2), p.123-135.

Johnson, M., & Lee, K. Predictive Maintenance in Modern Manufacturing. International Journal of Industrial Engineering. 2022. 38(4), p. 210-225.

Brown, T. Real-Time Diagnostics in Production Processes. Manufacturing Technology Review. 2021. 29(1), p. 56-70.

Kumar, R., & Patel, S. Challenges in Implementing Monitoring Systems in Small Enterprises. Journal of Production Engineering. 2024. 50(3), p. 89-102.

Georgian Industrial Association. Current State of Manufacturing in Georgia: Challenges and Opportunities. Tbilisi: GIA Press. 2023.

Copyright (c) 2025 Georgian Scientists

This work is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License.