Effect of highenergetic electrons irradiation on the fracture toughness characteristics of Si and Si+2at.%Ge wafers

Downloads

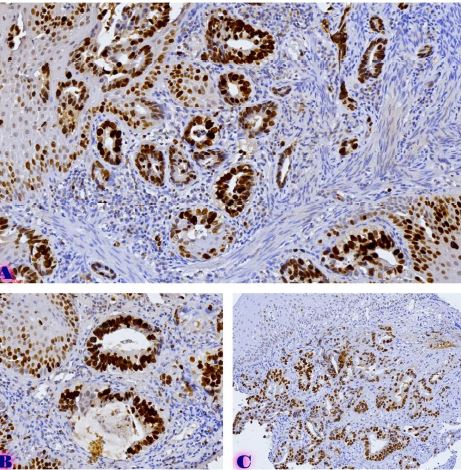

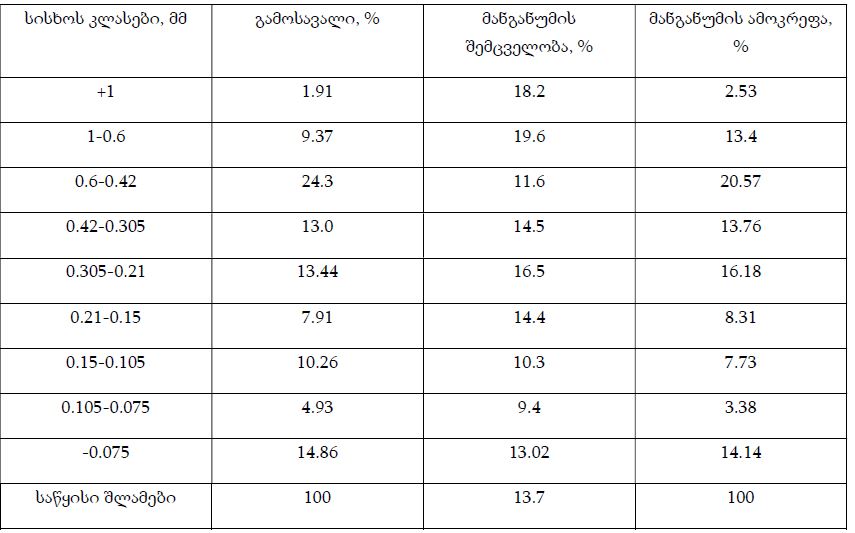

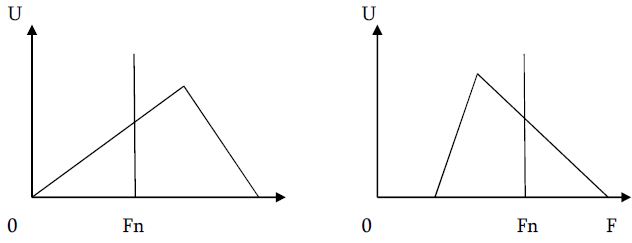

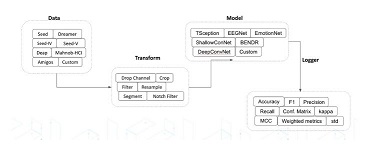

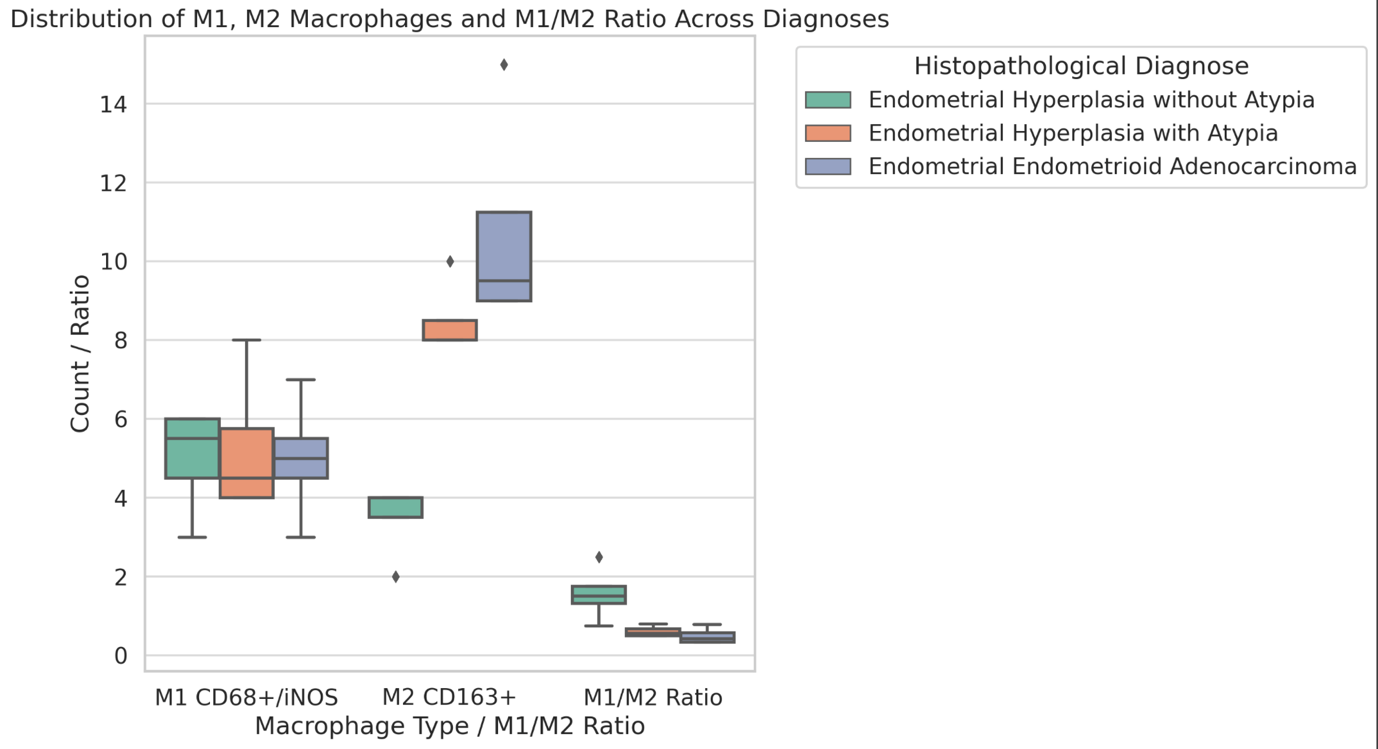

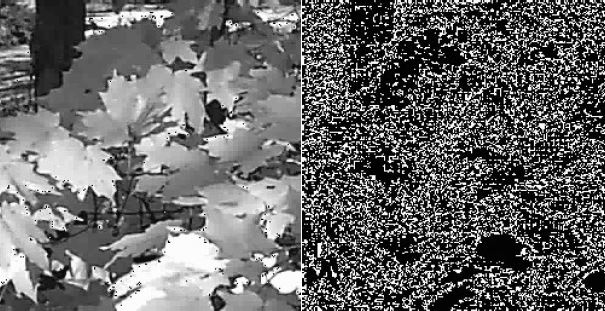

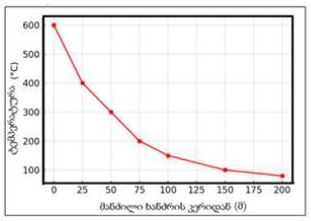

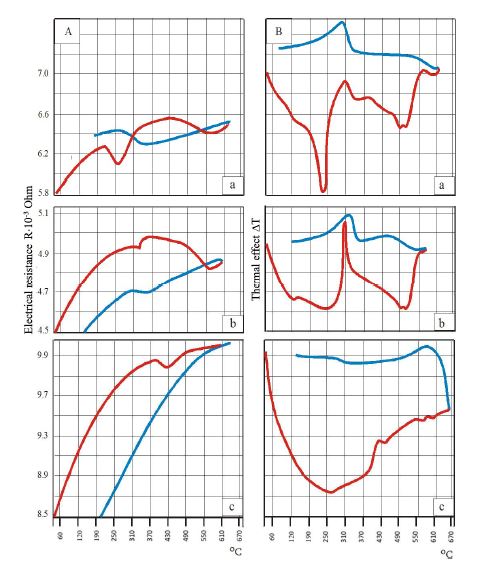

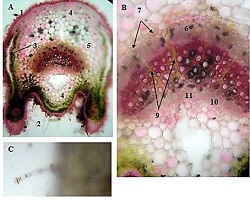

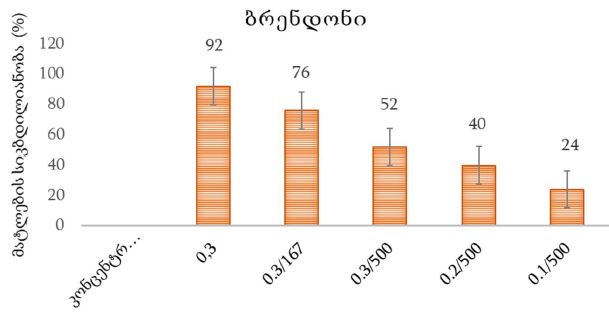

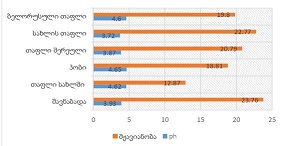

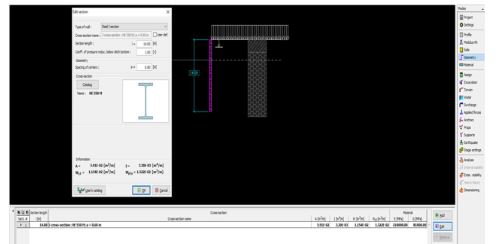

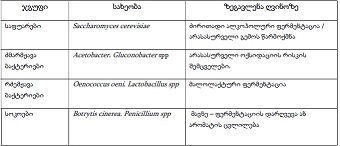

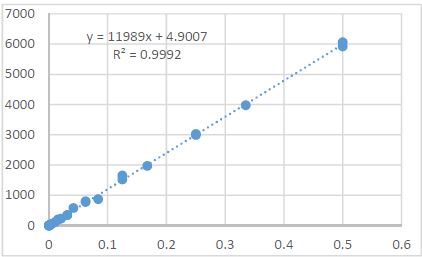

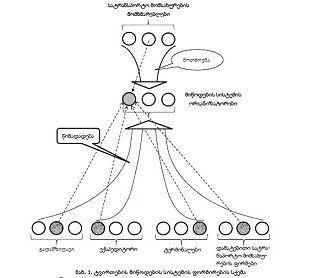

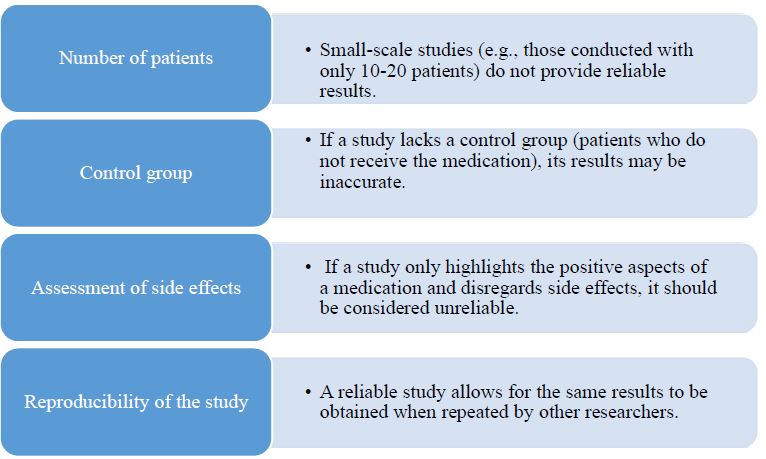

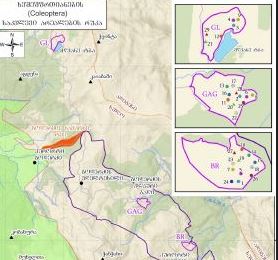

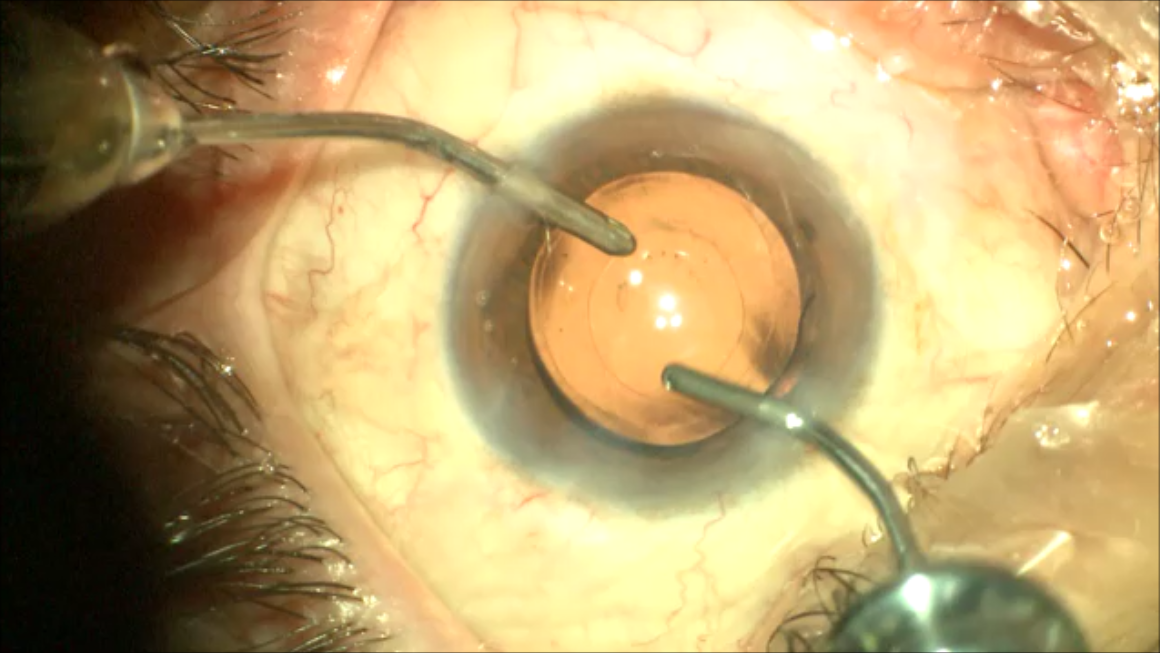

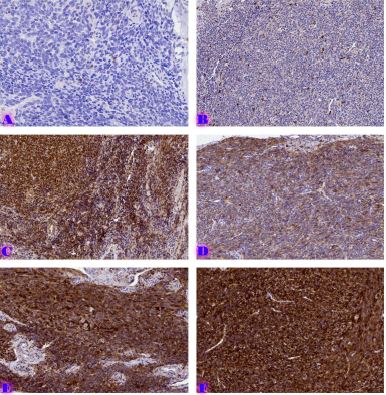

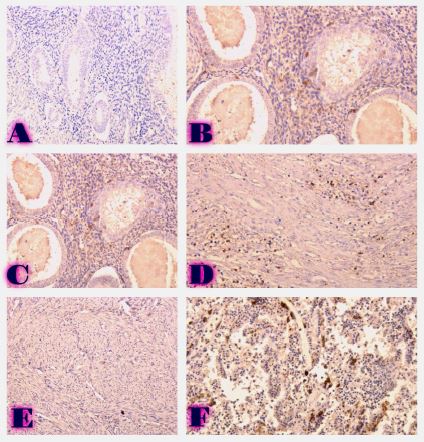

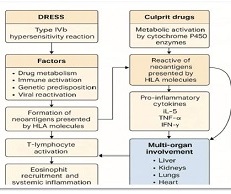

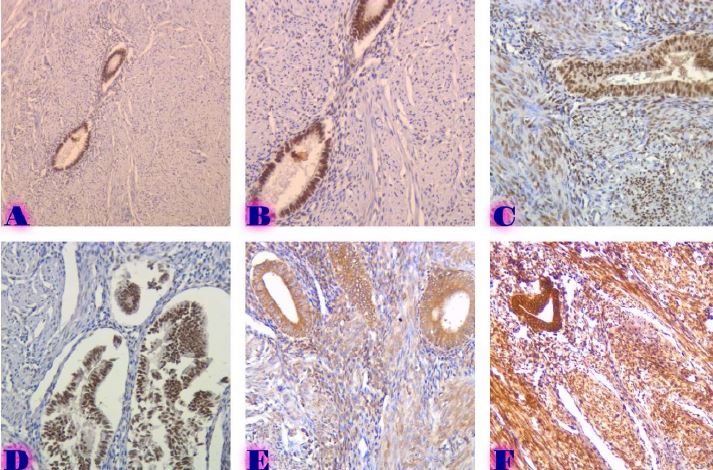

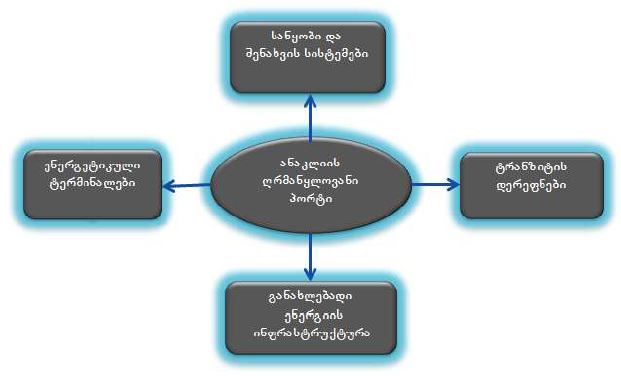

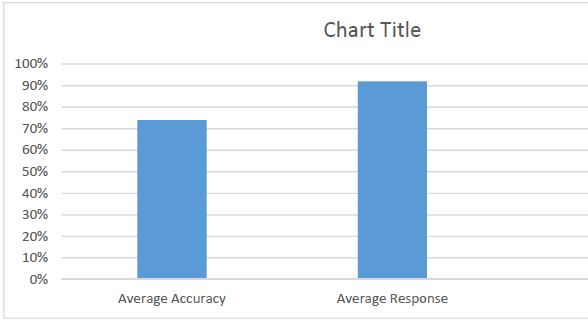

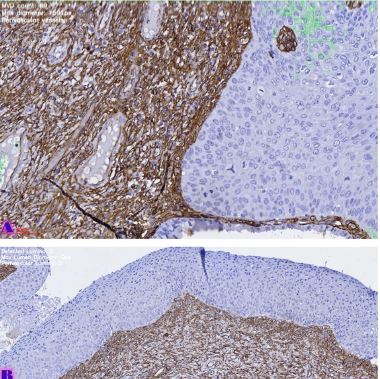

Crack resistance of silicon based materials wafers have a vital meaning in development of microelectromechanical systems technology. Nevertheless, there is currently little information about the mechanisms of crack formation, propagation and rupture deformation in the processes of indentation of semiconductor materials. Present paper deals with the investigation of elastic modulus, microhardness and crack-formation characteristics of the monocrystalline n-Si (100), p-Si (111) and p-Si+2at.%Ge wafers in the initial and 12 MeV energy electrons irradiated states, over a wide range of maximum applied load on the Vickers indenter. Measurements were performed by the Vickers method on Shimadzu DUH-211S system ultramicrotester at room temperature. It is shown that in the initial state (111) orientation p-Si substrates are characterized by relatively high elastic modulus and microhardness. Irradiation with high-energy electrons leads to an farther increase in the mechanical characteristics of all three samples, which is more expressed in p-type monocrystalline silicon. Based on the evaluation of the length of the cracks propagated along the diagonals of the residual impressions, the critical stress intensity factor for the cracks formation on the sample surface and the effective rupture energy are estimated. p-Si substrates on the (111) planes are characterized by high resistance to fracture toughness. Electron irradiation improves the fracture toughness characteristics of p-Si wafers. Crack resistance of the p-Si+2at.%Ge wafers is characterized by a slight increase in the electron-irradiated state. In indentation processes, the mechanical properties of the p-Si+2at%Ge wafers, including the fracture toughness characteristics, are determined by two opposing factors: softening associated with germanium atoms with large atomic radius and hardening associated with the formation of more high-strength beta-tin-modification SiGe-II phase during the indentation-stimulated phase transformation process.

Downloads

D.B.Marshall, B.R.Lawn and A.G.Evans J.Am.Ceram Soc., 63,(1982), 561-

R.F,Cook and G.M.Pharr. J.Am.Ceram. Soc., 73, (1990), 787-

W.C.Oliver and G.M.Pharr, J.Mater. Res, 7 (1192), 1567.

B.R.Lawn, A.G.Evans and D.B.Marshall. J.Am.Ceram Soc., 63, (1982), 1769-

J.S.Field, M.V.Swain, R.D.Dukino.J.Mater.Res.,vol.18,N6,(2003), 1412-1419.

GR.Anstis, P.Chantikul, Lawn B.R, et al. J.Am.Ceram.Soc.,(1981), 533-538.

F.Ebrahimi,L.Kalwani, J.Materials Science and Engineering, A268, (1999), 116-126.

Copyright (c) 2023 GEORGIAN SCIENTISTS

This work is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License.