Use of polymer dispersed liquid crystal (PDLC) film as a greenhouse cover material

Downloads

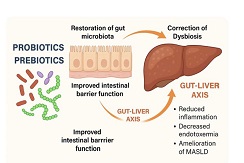

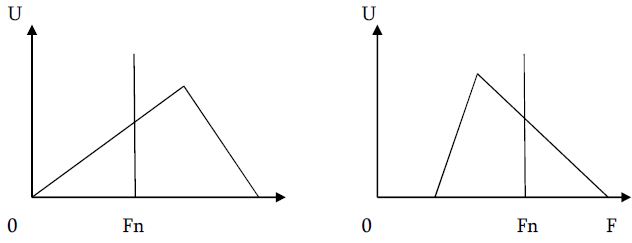

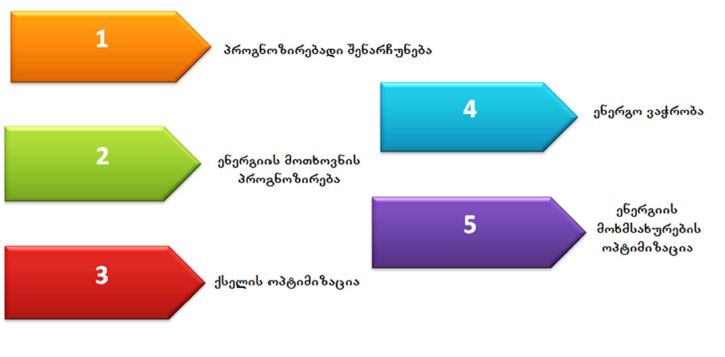

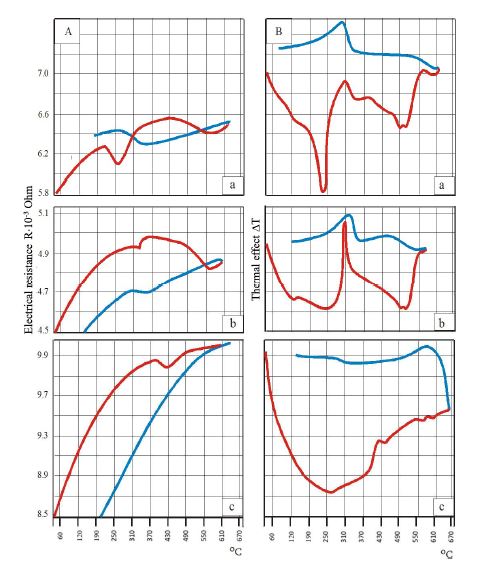

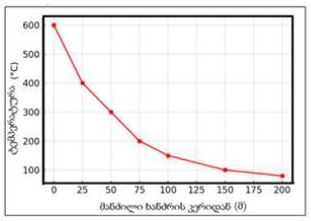

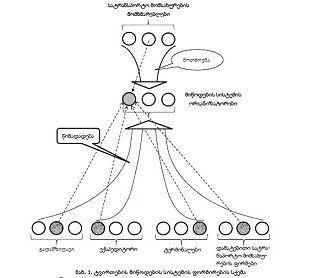

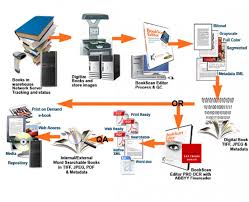

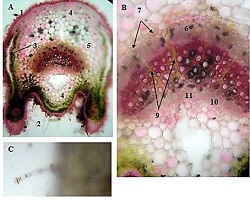

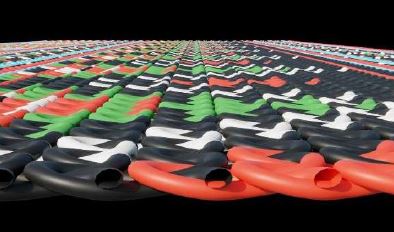

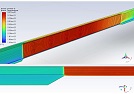

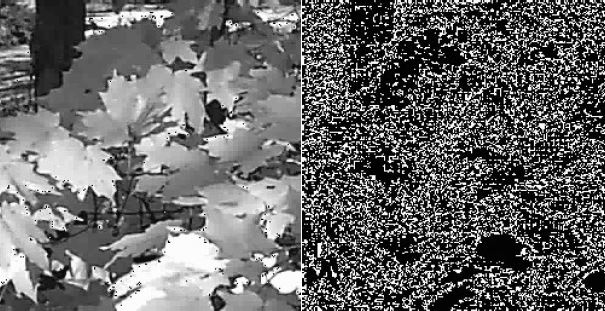

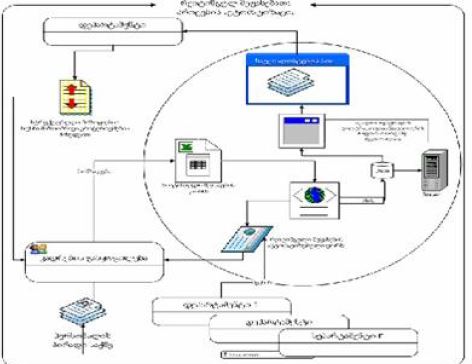

As of today, we can surely say that even the smallest and the most simple greenhouses can’t do without some automation, to say nothing of large enterprises. High-level automation is attained at the expense of all components available in the system, and all separate components have to smoothly perform their functions and duties. The reliable systems always have some fall-back options in cases of the failure of one or another component. Expansion in the number of electronic components naturally leads to increase of energy consumption, and one may say that it is an important factor forming the final product price. For maintenance of competitive ability any agricultural enterprise tries to offer such production on the market, which will be competitive compared to other types of production in terms of price and quality. Therefore, the agricultural enterprise from the very beginning makes efforts to establish as much energy-saving enterprise as possible that will have a beneficial impact not only on company budget, but will provide another one big step forward aimed to preservation of natural resources. Diminution of any energy resourse utilization means first of all their proper use and design of such greenhouse system, which uses the external climate conditions to the most benefit. The most important external climate factor for greenhouses, which generates other climate conditions is of course the sun. As we know, solar energy is the most important for plants, and in case of its deficiency the main growth processes will be inhibited, while in case of its redundancy, a plant may be damaged at all. In greenhouses the energy is mainly used for illumination, heating and cooling, while other microclimate parameters, such as CO2 and humidity, don’t require even a third part of energy consumption. It is obvious, that the precise indices of energy consumption depend on geographic location and specific plant crop. Based on the above-mentioned, it is necessary to use sun energy to the maximum efficiency in order to reduce energy consumption expenditures. Traditional microclimate automation systems control the mentioned factors by means of electric louvres or curtains, which provide shading adjustment, so that a sunlight passes upper greenhouse cover and reach internal shading structure. Based on the shading structure conditions, sunlight either is reflected or partially absorbed. The mentioned shading method has some negative aspects, first of all that its shading characteristics are permanent (unchanged), it has a fixed sun energy conductivity, permanent reflection and absorption coefficients, and it either can be used or not. Therefore, such kinds of shading methods can provide maximum efficiency only when the solar intensity exactly corresponds to parameters of the mentioned shading structure so that a plant receives exactly as much energy as is necessary for this specific plant crops and based on the specific “age” of this culture. Of course, we realize that it is virtually impossible to preserve so many parameters, since taking all the mentioned factors into account, precise natural illumination can be provided in some seasons only, and then only in some time of a day, for short period of time. In all other cases, a plant gets more or less illumination, or else the more time is needed. During most of the time, a greenhouse microclimate automation system is forced to balance microclimate parameters deviation, with turn-on heating, light and cooling that will surely cause additional energy consumption. Apart from the fact that the mentioned classic shading method doesn’t provide maximum efficiency during the most of time, it should be noted as well that a mentioned shading system is located in the inner part of the greenhouse and regardless of the material used for its manufacturing and its reflection characteristics a range of absorption coefficient is 8-15% in all cases, due to absorption of some solar energy, so the system is getting hot and further the heat will be transferred to the inner part of greenhouse, as a result a temperature parameter will change that leads to necessity of temperature decrease in the greenhouse, so a cooling system has to be turned on or outdoor air of lower temperature has to be let in that obviously will have an impact on energy consumption and microclimate. Based on the above mentioned, it is clearly seen that currently available greenhouse microclimate automation systems, and exactly shading systems don’t provide the desirable outcome, that leads to use of additional components in order to preserve the necessary microclimate. It should be also noted that deviation of one parameter, for instance temperature increase, results in change of other parameters, as well, including moisture concentration, so in order to balance a temperature, it is necessary to either let the outdoor air in or to use the cooling system. At this stage the necessary microclimate has been already disturbed, and afterwards due to entry of the outdoor air, even if this option is admissible, humidity and CO2 concentration are disrupted, whereafter the system is forced to spent energy resources with the purpose of maintenance of desirable microclimate parameters, cooling system has to be switched on, as well and all this leads to electric energy consumption. The presented paper offers a new method for natural illumination shading in the greenhouses, which will more precisely and effectively adjust the natural lighting; its use will also lead to less heating of the inner part of greenhouse, and the mentioned method will make it possible to perform exact and segment management of natural illumination in the greenhouses. Properties of electron toning films as a means for an alternate shading method and its comparison with other greenhouse cover materials have been discussed in the article. It has been shown that natural illumination adjustment using electron toning technology is more precise and provides high efficiency and reduction of energy consumption. An additional information will be published in the thesis work, where the model of shading system using electron toning technology developed on the basis of this efficiency indices will be represented, the operation principles will be discussed, appropriate protocols, interfaces will be selected and operation algorithm will be developed, by means of which the single parts of the greenhouse will be elaborated and natural lighting intensities will be adjusted.

Downloads

Copyright (c) 2024 Georgian Scientists

This work is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License.