For technological aspects of "smart" materials

Загрузки

Article about the mechanisms for obtaining effects self-healing of initial properties or any characteristics in various artificially created materials, such as polymers, ceramics, metals, composite materials, etc. The chemical and physical processes that cause the effects of self-healing are briefly considered, as well as examples and experimental prototypes of self-healing materials are given.

Скачивания

Метрики

Encyсlopedia of smart materials/[redactor Mel Schwartz]. New York: John Wiley and Sons, Inc., 2002; 1193 p.

Kessler M. Self-healing: a new paradigm in materials design // Proc. IMechE Part G: J. Aerospace Engineering. 2007. Vol. 221. P. 479-495.

Saavedra Flores E., Friswell M., Xia Y. Variable stiffness biological and bio-inspired materials // Journal of Intelligent Material Systems and Structures. 2013. Vol. 24. №5. P. 529–540.

Han B. et al. Smart concretes and structures: A review // Journal of Intelligent Material Systems and Structures. 2015. Vol. 26. №11. P. 1303–1345.

Huang H., Ye G. Self-healing of cracks in cement paste affected by additional Ca2+ ions in the healing agent // Journal of Intelligent Material Systems and Structures. 2015. Vol. 26. №3. P. 309–320.

Snoeck D. et al. Self-healing cementitious materials by the combination of microfibres and superabsorbent polymers // Journal of Intelligent Material Systems and Structures. 2014. Vol 25. №1. P. 13–24.

Shinya N., Kyono J., Laha K. Self-healing Effect of Boron Nitride Precipitation on Creep Cavitation in Austenitic Stainless Steel // Journal of Intelligent Material Systems and Structures. 2006. Vol. 17. P. 1127-1133.

Bor T. et al. Modeling of Stress Development During Thermal Damage Healing in Fiber-reinforced Composite Materials Containing Embedded Shape Memory Alloy Wires // Journal of Composite Materials. 2010. Vol. 44. № 22. P. 2547-2572.

M. Nosonovsky, P.K. Rohatgi. Biomimetics in material science. Springer, 2012. 415 p.

Olugebefola S. et al. Polymer Microvascular Network Composites // Journal of Composite Materials. 2010. Vol. 44. № 22. P. 2587-2603.

Fehrman B., Korde U. Targeted delivery of acoustic energy for self-healing // Journal of Intelligent Material Systems and Structures. 2013. Vol. 24. № 15. P. 1865-1887.

Soroushian P., Nassar R., Balachandra A. Piezo-driven self-healing by electrochemical phenomena // Journal of Intelligent Material Systems and Structures. 2013. Vol. 24(4). P. 441–453.

Atay H., Celik E. Multifunctional polymer composites: Antibacterial, flame retardant, radar absorbing and self-healing // Journal of Composite Materials. 2015. Vol. 49. № 20. P. 2469– 2482.

Williams H., Trask R., Bond I. A probabilistic approach for design and certification of self-healing advanced composite structures // Proceedings of the Institution of Mechanical Engineers Part O: J. Risk and Reliability. 2011. Vol. 225. P. 435-449.

Brancart J. et al. Atomic force microscopy–based study of self-healing coatings based on reversible polymer network systems // Journal of Intelligent Material Systems and Structures. 2014. Vol 25. №1. P. 40–46.

Phillips D., Baur J. A Granular Core for Self-healing, Variable Modulus Sandwich Composites // Journal of Composite Materials. 2010. Vol. 44. № 22. P. 2527-2545.

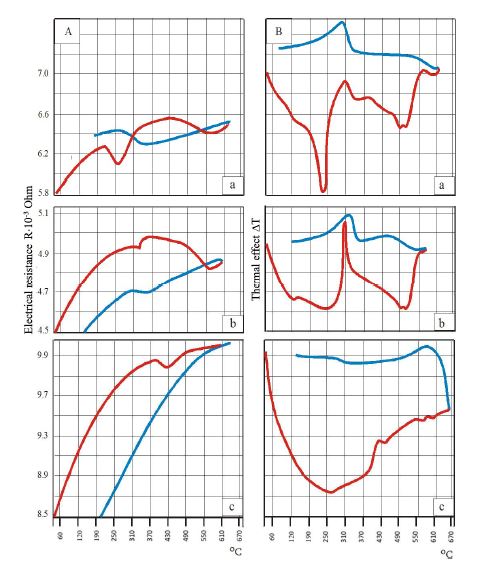

Haase T., Rohr I., Thoma K. Dynamic temperature measurements on a thermally activated self-healing ionomer // Journal of Intelligent Material Systems and Structures. 2014. Vol 25. № 1. P. 25–30.

Chen S. et al. Preparation of novel polytetrafluoroethylene/copper-matrix self-lubricating composite materials // Journal of Composite Materials. 2014. Vol. 48. № 13. P. 1561–1574.

Wang H. et al. Tribological performances on porous polyphenylene sulfide self-lubricating composites with super wear resistance // Journal of Thermoplastic Composite Materials. 2014. Vol 27. №1. P. 82–92.

Srikant R.R., Ramana V., Vamsi Krishna P. Development and performance evaluation of self-lubricating drill tools // Journal of Engineering Tribology. 2015. Vol. 229. № 12. P. 1479–1490.

Suiyuan C. et al. Synthesis of New Cu-based Self-lubricating Composites with Great Mechanical Properties // Journal of Composite Materials. 2011. Vol. 45. № 1. P. 51-63.

Suiyuan C. et al. Effect of BN fraction on the mechanical and tribological properties of Cu alloy/BN self-lubricating sleeves // Journal of Сomposite Materials. 2015. Vol. 49. №30. P. 3715–3725.

Singh S. et al. Microstructural analysis and tribological behavior of aluminum alloy reinforced with hybrid alumina/nano graphite particles // Journal of Engineering Tribology. 2015. Vol. 229. № 5. P. 597–608.

M. Nosonovsky, P.K. Rohatgi. Biomimetics in material science. Springer, 2012. 415 p.

Kong L. B., Cheung C. F., To S. Design, fabrication and characterization of threedimensional patterned microstructured surfaces with self-cleaning properties from hydrophilic materials // Journal of Engineering Manufacture. 2012. V. 226. №9. P. 1536– 1549.

Vorobyev A., Guo C. Multifunctional surfaces produced by femtosecond laser pulses // J. Appl. Phys. 2015. V. 117. № 3. DOI: 10.1063/1.4905616.

Scarratt L. et al. Durable Superhydrophobic Surfaces via Spontaneous Wrinkling of Teflon AF // ACS Appl. Mater. Interfaces. 2016. DOI: 10.1021/acsami.5b12165.

Ibrahim N., Refaie R., Ahmed A. Novel Approach for Attaining Cotton Fabric with MultiFunctional Properties // Journal of Industrial Textiles. 2010. Vol. 40. № 1. P. 65-83.

Sundaresan K. et al. Influence of nano titanium dioxide finish, prepared by sol-gel technique, on the ultraviolet protection, antimicrobial, and self-cleaning characteristics of cotton fabrics // Journal of Industrial Textiles. 2012. Vol. 41. № 3. P. 259-277.

Qi K., Wang X., Xin J. H. Photocatalytic self-cleaning textiles based on nanocrystalline titanium dioxide // Textile Research Journal. 2011. Vol. 81. № 1. P. 101-110.

Lee H. J., Kim J., Park C. H. Fabrication of self-cleaning textiles by TiO2-carbon nanotube treatment // Textile Research Journal. 2014. Vol 84. № 3. P. 267–278.

Ashraf M. et al. Study the multi self-cleaning characteristics of ZnO nanorods functionalized polyester fabric // Journal of Industrial Textiles. 2014. DOI: 10.1177/1528083714562086.

Ashraf M. et al. Photocatalytic solution discoloration and self-cleaning by polyester fabric functionalized with ZnO nanorods // Journal of Industrial Textiles. 2015. Vol. 44. № 6. P. 884–898.

Ranogajec J. et al. Protection of Cultural Heritage Objects with Multifunctional Advanced Materials // Progress in Cultural Heritage Preservation – EUROMED. 2012. P.255-258.

Goffredo G. B. et al. TiO2 nanocoatings for architectural heritage: Self-cleaning treatments on historical stone surfaces // Journal of Nanoengineering and Nanosystems. 2014. Vol. 228. № 1 P. 2–10.

Hadnadjev M. et al. Design of self-cleaning TiO2 coating on clay roofing tiles // Philosophical Magazine. 2010. V. 90. № 22. P. 2989-3002.

Yanılmaz M., Sarac A. S. A review: effect of conductive polymers on the conductivities of electrospun mats // Textile Research Journal. 2014. Vol. 84. № 12. P. 1325–1342.

https://worldofmaterials.ru/spravochnik/special-materials/200-provodyashie-polymeri

Ates M., Kalender O. Comparison of anticorrosion behavior of polyaniline and poly(3,4- methylenedioxyaniline) and their titanium dioxide nanocomposites //High-Performance Polymers. 2015. Vol. 27. № 6. P. 685–693.

Tiitu M. et al. Aminic epoxy resin hardeners as reactive solvents for conjugated polymers: polyaniline base/epoxy composites for anticorrosion coatings //Polymer. 2005. V. 46. P. 6855–6861.

Muthukumar N., Thilagavathi G., Kannaian T. Polyaniline-coated polyurethane foam for pressure sensor applications //High-Performance Polymers. 2015. DOI: 10.1177/0954008315583703.

Hoghoghifard S., Mokhtari H., Dehghani S. Improving the conductivity of polyaniline coated polyester textile by optimizing the synthesis conditions // Journal of industries textiles. 2015. DOI: 10.1177/1528083715594981.

Muthukumar N., Thilagavathi G., Kannaian T. Polyaniline-coated nylon lycra fabrics for strain sensor and electromagnetic interference shielding applications //High-Performance Polymers. 2015. Vol. 27. № 1. P. 105–111.

Yu J. et al. Flame retardancy and conductive properties of polyester fabrics coated with polyaniline // Textile Research Journal. 2015. DOI: 10.1177/0040517515606360.

Prasanna G.D. Synthesis and characterization of magnetic and conductive nickel ferrite– polyaniline nanocomposites // Journal of Composite Materials. 2015. Vol. 49. № 21. P. 2649–2657.

Kumar V. et al. Mechanical and electrical properties of PANI-based conductive thermosetting composites // Journal of Reinforced Plastics and Composites. 2015. Vol. 34. № 16. P. 1298–1305.

Kizildag N. et al. Polyacrylonitrile/polyaniline composite nano/microfiber webs produced by different dopants and solvents // Journal of Industrial Textiles. 2015. DOI: 10.1177/1528083715598654.

Kizildag N. et al. Polyacrylonitrile/polyaniline composite nanofiber webs with electrostatic discharge properties // Journal of Composite Materials. 2016. DOI: 10.1177/0021998316630583.

Eren O. et al. Synergistic effect of polyaniline, nanosilver, and carbon nanotube mixtures on the structure and properties of polyacrylonitrile composite nanofiber // Journal of Composite Materials. 2015. DOI: 10.1177/0021998315601891.

Al-Ghamdi A.A. et al. On the prospects of conducting polyaniline/natural rubber composites for electromagnetic shielding effectiveness applications // Journal of Thermoplastic Composite Materials. 2014. Vol. 27. № 6. P. 765–782.

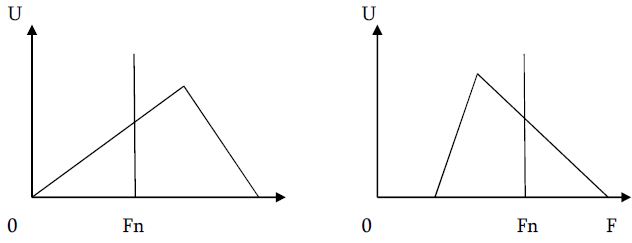

Lam Y.-Z., Swingler J., McBride J. W. The Contact Resistance Force Relationship of an Intrinsically Conducting Polymer Interface // IEEE Transactions on Components and Packaging Technologies. 2006. Vol. 29. № 2. P. 294-302.

Ghaffari A., Hashemabadi S. H., Ashtiani M. A review on the simulation and modeling of magnetorheological fluids // Journal of Intelligent Material Systems and Structures. 2015. Vol. 26. № 8. P. 881–904.

Vereda F., de Vicente J., Hidalgo-Alvarez R. Effect of surface roughness on the magnetic interaction between micron-sized ferromagnetic particles: Finite element method calculations // Journal of Intelligent Material Systems and Structures. 2016. doi: 10.1177/1045389X15624793.

Spaggiari A., Dragoni E. Enhanced properties of magnetorheological fluids: Effect of pressure // Journal of Intelligent Material Systems and Structures. 2015. Vol. 26. № 14. P. 1764–1775.

Guth D., Maas J. Long-term stable magnetorheological fluid brake for application in wind turbines // Journal of Intelligent Material Systems and Structures. 2016. DOI: 10.1177/1045389X15624794.

Iglesias G. R. et al. Stability behavior of composite magnetorheological fluids by an induction method // Journal of Intelligent Material Systems and Structures. 2015. Vol. 26. № 14. P. 1836–1843.

Freyer H. et al. Scale effects of the rheological properties of electrorheological suspensions // Journal of Intelligent Material Systems and Structures. 2015. Vol. 26. № 14. P. 1856–1860.

Ma L., Zheng F., Zhao X. Sedimentation behavior of hierarchical porous TiO2 microspheres electrorheological fluids // Journal of Intelligent Material Systems and Structures. 2015. Vol. 26. № 14. P. 1936–1944.

Korobko E. V. et al. Time stability studies of the electrorheological response of dispersions with different types of charge carriers // Journal of Intelligent Material Systems and Structures. 2015. Vol. 26. № 14. P. 1782–1788.

Borin D., Stepanov G. Elastomer with magneto- and electrorheological properties // Journal of Intelligent Material Systems and Structures. 2015. Vol. 26. № 14. P. 1893–1898.

Eshaghi M., Sedaghati R., Rakheja S. Dynamic characteristics and control of magnetorheological/electrorheological sandwich structures: A state-of-the-art review // Journal of Intelligent Material Systems and Structures. 2015. doi: 10.1177/1045389X15620041.

Vacareanu L., Catargiu A.-M., Grigoras M. Spectroelectrochemical characterization of isomeric conjugated polymers containing 2,7- and 3,6-carbazole linked by vinylene and ethynylene segments //High-Performance Polymers. 2015. Vol. 27. № 4. P. 476–485.

Xu N. et al. A facile process for the preparation of polyaniline/polyacrylic acid composite electrochromism films //High-Performance Polymers. 2011. Vol. 23. № 7. P. 489-493.

Mardaljevic J., Waskett R. K., Painter B. Neutral daylight illumination with variable transmission glass: Theory and validation // Lighting Res. Technol. 2015. Vol. 0. P. 1–19. DOI: 10.1177/1477153515620339.

Wang M. et al. Binary Solvent Colloids of Thermosensitive Poly(N-isopropyl acrylamide) Microgel for Smart Windows // Industrial & Engineering Chemistry Research. 2014. V. 53. № 48. P. 18462–18472. DOI: 10.1021/ie502828b.

Nonoyama T., Gong J. P. Double-network hydrogel and its potential biomedical application: A review // Journal of Engineering in Medicine. 2015. Vol. 229. № 12. P. 853–863.

Zhang D. et al. Electroactive hybrid hydrogel: Toward a smart coating for neural electrodes // Journal of Bioactive and Compatible Polymers. 2015. Vol. 30. № 6. P. 600–616.

M. Jaiswal, V. Koul. Assessment of multicomponent hydrogel scaffolds of poly(acrylic acid2-hydroxy ethyl methacrylate)/gelatin for tissue engineering applications // Journal of Biomaterials Applications. 2013. V. 27. № 7. P. 848–861.

Cometa S. et al. Analytical characterization and antimicrobial properties of novel copper nanoparticle–loaded electro synthesized hydrogel coatings // Journal of Bioactive and Compatible Polymers. 2013. V. 28. № 5. P. 508–522. DOI: 10.1177/0883911513498960.

Kim Y. S. et al. Thermoresponsive actuation enabled by permittivity switching in an electrostatically anisotropic hydrogel // Nature Materials. 2015. V.14. P. 1002–1007. DOI: 10.1038/nmat4363.

Sobczyk M., Wallmersperger T. Modeling and simulation of the electrochemical behavior of chemically stimulated polyelectrolyte hydrogel layer composites // Journal of Intelligent Material Systems and Structures. 2015. DOI: 10.1177/1045389X15606997.

Reynolds M., Daley S. Enhancing the band gap of an active metamaterial // Journal of Vibration and Control. 2015, DOI: 10.1177/1077546315600330.

P. F. Pai. Metamaterial-based Broadband Elastic Wave Absorber // Journal of Intelligent Material Systems and Structures. 2010. Vol. 21. P. 517-528.

Restrepo-Flórez J. M., Maldovan M. Mass Separation by Metamaterials // Scientific Reports. 2016. V. 6. DOI: 10.1038/srep21971.

Weis J., Swager T. Thiophene-Fused Tropones as Chemical Warfare Agent-Responsive Building Blocks // ACS Macro Lett. 2015. V. 4. №1. P. 138–142.

Ackerman E. 4-D Printing Turns Carbon Fiber, Wood Into Shapeshifting Programmable Materials // IEEE Spectrum. 2014. URL: http://spectrum.ieee.org/techtalk/computing/hardware/4d-printing-turns-carbon-fiber-wood-into-shapeshiftingprogrammable-materials.

Correa D. et al. 3D-Printed Wood: Programming Hygroscopic Material Transformations // 3D Printing and Additive Manufacturing. 2015. Vol. 2. № 3. P. 106-116. DOI: 10.1089/3dp.2015.0022.