Engineering design approaches and a comparative study of topology optimization tools

Downloads

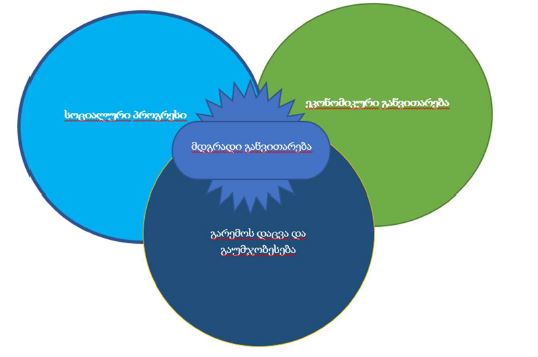

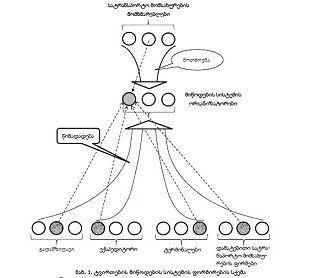

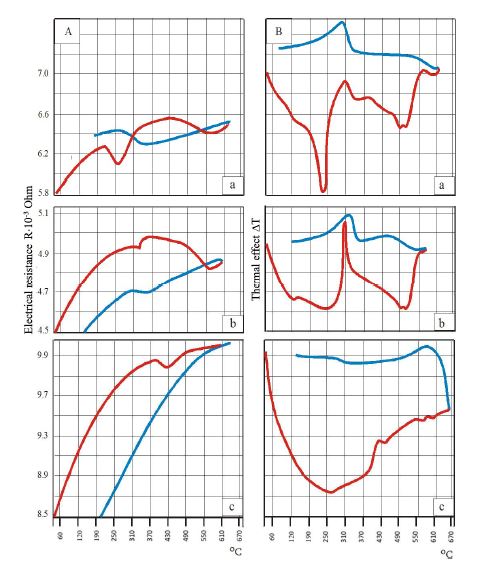

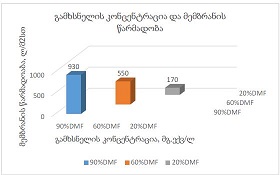

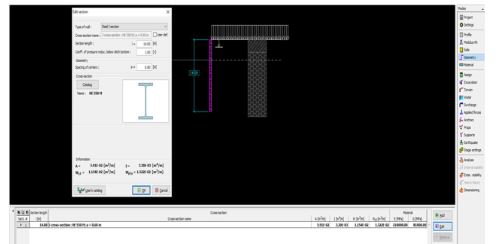

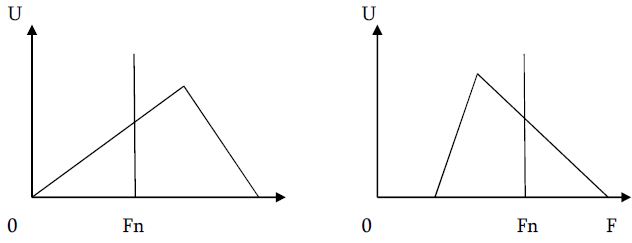

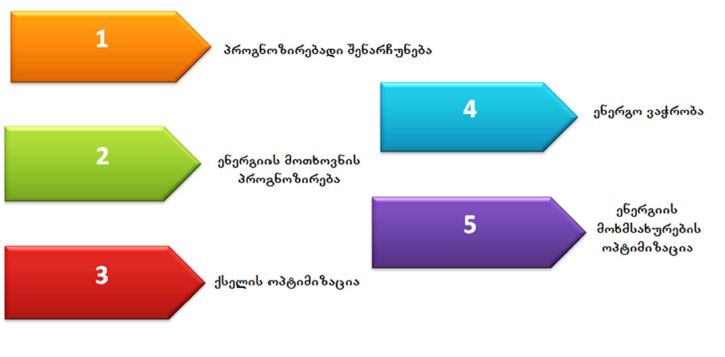

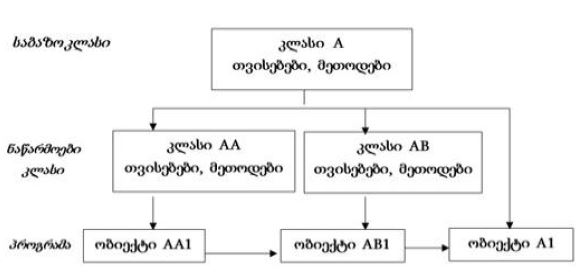

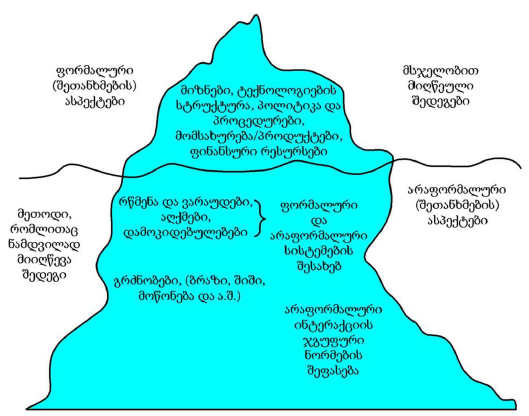

In the paper there are presented engineering approaches of generative design, the authors note that the advent of additive manufacturing AM (Additive Manufacturing) reveals the limits of current computer-aided design CAD (Computer Aided Design) systems and, at the same time, emphasizes topology optimization TO (Topology Optimization) and generative design of the potential of GD (Generative Design) tools, that have not been fully exploited until now. In contrast to the traditional approach to design, where designers take a dominant role at each stage of the engineering design process, the paper notes that the introduction of such tools in the product development process leads to simulation design approaches, which implies a significant change in the designer's role. For this purpose, the paper presents a comparison of two different additive manufacturing design methods, namely TO and GD on products obtained using tools. The comparison aims to reflect the evolution of the traditional approach when using TO and GD tools, and to highlight the potential and limitations of these optimization tools when integrated with CAD systems. In addition, this comparative study itself can be a useful and practical source for designers to identify the most suitable approach based on their needs and project resources. A comparative study is conducted by examining a prototype rocker arm and brake pedal design for a Formula Student racing car. Their results, in terms of mechanical performance, show that TO and especially GD tools can be effectively used early in the AM-oriented design process to modify components and make them lighter and stronger.

Downloads

Tang, Y.; Zhao, Y.F. A survey of the design methods for Additive Manufacturing to improve functional performance. Rapid Prototyp. J. 2016, 22, 569–590.

Wiberg, A.; Persson, J.; Ölvander, J. Design for Additive Manufacturing—A review of available design methods and software. Rapid Prototyp. J. 2019, 25, 1080–1094.

Levy, G.N.; Schindel, R.; Kruth, J. Rapid manufacturing and rapid tooling with layer manufacturing (LM) technologies, state of the art and future perspectives. CIRP Ann. 2013, 52, 589–609.

Kruth, J.-P.; Leu, M.C.; Nakagawa, T. Progress in Additive Manufacturing and Rapid Prototyping. CIRP Ann. Manuf. Technol. 1998, 47, 525–540.

Vandenbroucke, B.; Kruth, J.-P. Selective laser melting of biocompatible metals for rapid manufacturing of medical parts. Rapid Prototyp. J. 2007, 13, 196–203.

Leal, R.; Barreiros, F.; Alves, M.; Romeiro, F.; Vasco, J.C.; Santos, M.; Marto, C. Additive Manufacturing tooling for the automotive industry. Int. J. Adv. Manuf. Technol. 2017, 92, 1671–1676.

Ituarte, I.F.; Chekurov, S.; Tuomi, J.; Mascolo, J.E.; Zanella, A.; Springer, P.; Partanen, J. Digital manufacturing applicability of a laser sintered component for automotive industry: A case study. Rapid Prototyp. J. 2018, 24, 1203–1211.

Ngo, T.D.; Kashani, A.; Imbalzano, G.; Nguyen, K.T.Q.; Hui, D. Additive Manufacturing (3D printing): A review of materials, methods, applications and challenges. Compos. Part B Eng. 2018, 143, 172–196.

Elsayed, M.; Ghazy, M.; Youssef, Y.; Essa, K. Optimization of SLM process parameters for Ti6Al4V medical implants. Rapid Prototyp. J. 2019, 25, 433–447.

Dankwort, C.W.; Weidlich, R.; Guenther, B.; Blaurock, J.E. Engineers’ CAx education—It’s not only CAD. Comput. Aided Des. 2004, 36, 1439–1450.

Barbieri, L.; Calzone, F.; Muzzupappa, M. Form and function: Functional optimization and Additive Manufacturing. In Advances on Mechanics, Design Engineering and Manufacturing II; Springer: Cham, Switzerland, 2019; pp. 649–658.

Bathe, K.J. Finite Element Procedures; Prentice Hall: Upper Saddle River, NJ, USA, 1996.

Sandberg M. Design for Manufacturing: Methods and Applications Using Knowledge Engineering. Ph.D. Dissertation, Luleå Tekniska Universitet, Luleå, Sweden, 2007.

Thompson, M.K.; Moroni, G.; Vaneker, T.; Fadel, G.; Campbell, R.I.; Gibson, I.; Bernard, A.; Schulz, J.; Graf, P.; Ahuja, B.; et al. Design for Additive Manufacturing: Trends, opportunities, considerations, and constraints. CIRP Ann. 2016, 65, 737–760.

Pagac, M.; Hajnys, J.; Halama, R.; Aldabash, T.; Mesicek, J.; Jancar, L.; Jansa, J. Prediction of Model Distortion by FEM in 3D Printing via the Selective Laser Melting of Stainless Steel AISI 316L. Appl. Sci. 2021, 11, 1656.

Afazov, S.; Denmark, W.A.D.; Lazaro Toralles, B.; Holloway, A.; Yaghi, A. Distortion prediction and compensation in selectivelaser melting. Addit. Manuf. 2017, 17, 15–22.

Sotomayor, N.S.; Caiazzo, F.; Alfieri, V. Enhancing Design for Additive Manufacturing Workflow: Optimization, Design and Simulation Tools. Appl. Sci. 2021, 11, 6628.

Bendsoe, M.P.; Sigmund, O. Topology Optimization: Theory, Methods, and Applications; Springer: Berlin/Heidelberg, Germany, 2003.

Bendsøe, M.P. Optimization of Structural Topology, Shape, and Material; Springer: Berlin/Heidelberg, Germany, 1995.

Sigmund, O.; Maute, K. Topology Optimization Approaches: A comparative review. Struct. Multidiscip. Optim. 2013, 48, 1031–1055.

Barbieri, L.; Muzzupappa, M. Performance-Driven Engineering Design Approaches Based on Generative Design and Topology Optimization Tools: A Comparative Study. Appl. Sci. 2022, 12, 2106. https://doi.org/10.3390/app12042106

Copyright (c) 2023 GEORGIAN SCIENTISTS

This work is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License.